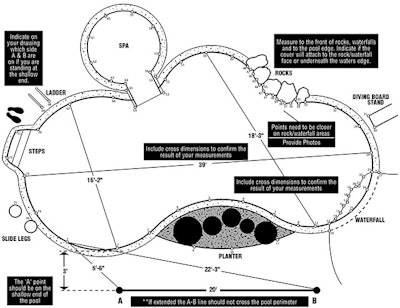

Sample point-to-point order form. This form standardizes the information and makes it easier for the CAD department to plot the cover out and send you a plan to check against the pool.

Sample point-to-point order form. This form standardizes the information and makes it easier for the CAD department to plot the cover out and send you a plan to check against the pool.

Each year, it seems, another piece of new technology replaces an old job in the pool business. Skilled pool draftsmen have been sidelined by CAD design software, experts in titration and chemistry are being crowded out by water-testing stations, and the serviceroute planner's job now belongs to a phone app. Does the art of A-B safety cover measurement — a manual skill passed from the old timers to the new recruits for generations — face the same fate?

We called Tara Manufacturing's Kim Mitten and Gregg Minton for comments about the future of a method each has spent a career perfecting and teaching. They're keenly aware these specialized skills will go from ubiquity to near oblivion as measuring apps and apparatus take over the safety-cover marketplace in the coming years. Their own employer is even hastening this revolution with a laser-measuring device that will hit the market soon.

"We have a new product called Anchor Locator that we brought out at trade shows this past year. The response was very enthusiastic," says Mitten, Tara's Midwest regional sales manager. "We've already got orders for them and haven't even sent out the first one yet!"

RELATED: PHTA Shares Progress on Pool Cover, Pump Motor Regs

Still, despite this electronic encroachment into his territory, Mitten says there are companies who'll insist on training new hires on the tried-andtrue A-B measurement.

"The old way will always be around because you've got people who will just never embrace new technology," adds Minton, Mitten's long-time colleague who handles sales in the Southeast. "So I'm always going to have to remember how to do the A-B, no matter what comes out in the future. 'Want to try this new way?' Nah. That's not for me."

For readers who fit that description, we asked Mitten and Minton to share the fundamentals of good A-B measurement, and to point out some of the pitfalls that await the impatient and improperly prepared.

Gregg Minton (center) offers depth measurement instruction to workers from ASP.

Gregg Minton (center) offers depth measurement instruction to workers from ASP.

PICK YOUR POINTS

The basics of A-B measurement are pretty simple, and anyone who can follow instructions should be able to learn how to do it in the three hours it takes for an average measurement. In fact, after a 40-minute phone interview Mitten declared this writer ready to step in and help him measure a pool. (He's probably giving me too much credit, but his point is well taken.)

"You're measuring from two fixed points — the A and the B," he explains. "Your A and B points need to be a minimum of 15 feet apart, but they can be as far away from the pool as you want, as long as they're at least 3 feet from the pool. A lot of people like to go 4 feet, but 3 is fine. Even better is 5 feet."

In addition to the spacing between the points and the minimum distance from the pool, you want to make sure they are on a flat surface, that there are no obstacles between the points and that a line drawn between them does not cross any water.

"If you envision the line going between A and B and into infinity in both directions, no part of that line can cross water or even come within 3 feet of the pool," says Minton, who, like Mitten, has been measuring for safety covers and teaching the method for years.

Once you've chosen your spots, you will need to plant stakes on the deck or in the ground to hold one end of the tape measure you'll be using. Mitten keeps a variety of parts in his vehicle for this purpose.

"If there's a crack in the deck, I can put a screw in there," he says. "For saw cuts, I've got standard skimmer screws. I've got long 18-inch nails that I can put back behind the deck in the dirt. I carry a little bit of everything, and so far I've never come across a pool I can't figure out how to measure."

Before moving on to the next step, mark down the exact distance between those A and B points. Tara and all the other safety-cover manufacturers have forms dealers can use to record this measurement and the distance between each of the stakes and all of the points you'll be marking out and numbering around the perimeter of the pool. This is a good time to double-check that the points are at least 15 feet, at least 3 feet from the pool, and that there is no water or other obstructions within 3 feet of an imaginary line drawn between them and extending in either direction.

Measurement across the pool to a fixed point A. Minton marks points along the pool with chalk or masking tape.

Measurement across the pool to a fixed point A. Minton marks points along the pool with chalk or masking tape.

MAKE YOUR MARKS

Having set your stakes, the next step is marking off your measurement points around the pool. A good rule of thumb is to place them 2 feet apart, though the pool's shape will provide more specific guidance.

"The thing to pay attention to is the shape of that wall that you're measuring," Minton says. "If part of the pool is a straight line, three points is all you need, which is one on each end and one in the middle. Now, when you get into radiuses, the bigger the radius the farther apart the points can be, and the tighter the radius the closer together they'll need to be."

Mitten says when he's teaching someone how to mark off a pool for measurement, he has them picture a connect-the-dots drawing. Sure, you can provide a rough outline of the picture with very few points, but more points will more accurately reflect the shape. That said, people can go overboard and make more marks than they need, in Mitten's opinion.

"A lot of people will just put marks all the way around the pool at 3-foot intervals, but I am not a believer in that," he says. "Think to yourself, 'Can I draw the shape of the pool if I put a point here, a point here, a point here?' That's how I always think about it as I'm going around the pool. If you're unsure, though, you should err on the side of keeping them closer together."

RELATED: Automatic Pool Covers: The Everyday Essential

When you pick your spots, make sure you're moving clockwise, making marks and numbering them right next to the edge where the coping rolls over into the pool. It's also important to account for steps, ladders, diving board mounts and anything else that's within 18 inches of the pool. Minton marks his marks with chalk, though masking tape or duct tape will also work. Mitten is a rebel in that he uses neither, and instead measures the A and B at the same time and on the fly, noting the points in a notebook or on a voice recorder as he goes around the pool. The upside to this is it takes less time. The downside is considerable: There is no backup, and something as simple as an entry error means a complete do-over. Mitten doesn't worry about this; you probably should.

"Kim tends to do more of what I would call a 'freestyle' measurement," Minton says, laughing. "I'm a lot more regimented than he is, especially when I'm teaching people how to do it.

"The danger in doing it that way is when you're dealing with people who aren't really familiar with the process," Minton adds. "There's always the opportunity to record a wrong dimension, to skip a point or to read the tape wrong. If that happens, the CAD department will send you a message that the pool is not plotting out correctly: 'We need to verify point number 23.' Well, if you made marks around the pool and you know where your A-B points were you can go back and take that measurement again." Correcting an error this way won't work if you remove your stakes or forget where you put them, so leave them in if you can until the manufacturer lets you know you've done your measuring correctly. But even under ideal circumstances with chalk marks left on the pool, remeasurements require another unbillable appointment with the homeowner.

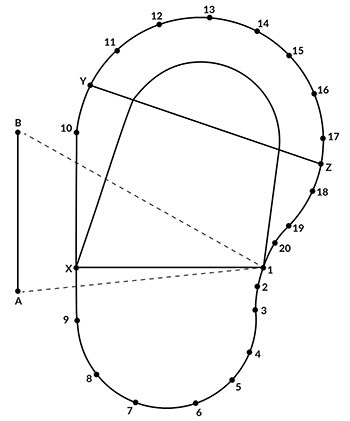

Sample pool measurement schematic showing some of the major A-B measurement rules.

Sample pool measurement schematic showing some of the major A-B measurement rules.

The basic theory of A-B measurement. The measured distance to two fixed points, A and B, locks in the location of each numbered point along the pool wall.

The basic theory of A-B measurement. The measured distance to two fixed points, A and B, locks in the location of each numbered point along the pool wall.

MAKE THE MEASUREMENTS

Setting aside the idea of using two tapes to measure the As and Bs at the same time like Mitten does, you will want a tape measure long enough to get to the furthest areas of the pool. You will use that tape to go clockwise around the pool and record the distance from the A stake to each numbered spot, then go back and anchor the tape to the B stake and measure the distance to each point again. Mitten says two 100-foot fiberglass tapes in different colors suit his purposes. You will only need one to measure each separately. This takes more time, but you avoid tangling the tapes and it helps prevent entry errors.

Though he sometimes goes it alone, he only does that if he has to. Having a second pair of hands there always helps, he says.

"You should have somebody writing and somebody measuring," Mitten says. "We also have an A-B app that the second person can use to record the measurements as the first person calls them out. The advantage of using the app is that as you enter the measurements it makes a picture of the pool. That makes it pretty easy to see when you've recorded a measurement wrong."

No matter what cover manufacturer you are using, they are sure to have a form for you to fill out with the location of the A and B points, the distance between them and columns for recording the distance from point A to every point and from point B to every point. This form standardizes the information and makes it easier for the CAD department to plot the cover out and send you a plan to check against the pool.

In a crew with one experienced member and one trainee, Mitten and Minton prefer to be the ones doing the writing or entering as the other person stretches the tapes taut and reads off the measurements.

"That's how I always do it when I'm teaching somebody," Minton says. "I'm always looking at the numbers above and watching where they are on the pool, and I've got in my mind whether the next reading should be a little bit further away or a little closer than the last one."

RELATED: Covers Go Custom

He was recently out on a job where the second man kept misreading the tape and giving him incorrect numbers. He'd report a 31 as 13, a 21 as 12, etc. "Now, if you're not paying close attention you can do that several times and send it in. Then, if you don't have the marks numbered on the deck around the pool, you'll have to do the whole thing over again," he says.

Some people just record the measurements on a piece of notebook paper. This can work when someone is experienced, but it increases the chances something will be forgotten.

The printed form will have an area to sketch out the shape of the pool, which helps the CAD team quickly identify problems. Some people attach graph paper, with 1 foot equal to one box on the paper, to create an image that's as accurate as possible. These people are few and far between. The greater number just rough out a drawing freehand. That's almost always fine — artistry doesn't count for much here. The manufacturer is merely looking to confirm the CAD drawing is pretty close to the sketch.

"We just want to get the general shape of the pool so that when the CAD department gets the drawing done they can say, 'Yeah, this sort of resembles this,'" Minton says. "A lot of people aren't artists. I'm certainly not!"

The final product is a perfect fit and a well-protected pool.

The final product is a perfect fit and a well-protected pool.

POSSIBLE PITFALLS

Sometimes a set of measurements will come in with the A and B columns reversed, or a person will travel the wrong way around a pool. Here's where the drawing comes in handy, as the CAD department will be able to see the cover will be manufactured upside down if they don't identify and correct the errors.

"We'll CAD it out, so we can see what the configuration of the cover is," Mitten explains. "If something is askew it should show up on CAD."

If this backstop fails and a cover is manufactured upside down, the dealer is held responsible and will have to pay for another cover to be made. Can't it simply be turned upside down and strapped on that way?

"Nope. That's a new cover," Minton explains. "Based on the shape of the pool we put wear strips on the bottom of the cover that extend out about 18 inches from the edge. Those wear strips are designed to come in contact with the coping, so the coping doesn't prematurely deteriorate the strapping of the material. So if you turn a cover upside down, your rub strips are going to be on top and won't serve their purpose."

Other than simple clerical errors or upside-down orientations, the most common mistake measurers make is failing to indicate what Mitten calls "specials."

"Some of the biggest problems are they don't necessarily mark down where there's a slide leg sticking in, or there's a water feature of some type that we have to go around," Mitten says. "The cover for a shaped pool will have an 18-inch overlap onto the deck, so if you've got something closer than that, then you have to actually put points for that on your A-B so that we can locate that. You tell us what it is — say it's an inch-and-a-half pipe — so we can build the cover to go around those obstacles."

Minton is a patient teacher and knows that while these procedures may intimidate the uninitiated, each step is easily completed with just a little bit of care. "It all comes down to paying attention to detail," he says. "I tell people all the time that measuring, whether for a liner or a cover, is not rocket science. But it is an exact science."

We asked Minton whether he mourned the way this old science is being replaced by a newer, electronic science.

"I've been developing my method for years, and I am always open to doing something different if I find something else works better," he says. "But, to be honest, if I am doing a pool I'll take the technology in a heartbeat!"