Despite the settled standards for swimming pool water chemistry, there's a powerful argument to be made for rethinking one of the most fundamental aspects of water treatment: the relationship between chlorine and cyanuric acid. Here, chemical consultant and author Robert Lowry makes his case.

The swimming pool industry has long embraced the recommended standard for chlorine concentrations of 1 to 3 ppm or 2 to 4 ppm, depending on who's doing the recommending. The industry has also observed a recommended cyanuric acid range of 10 to 100 ppm, a range that is viewed as necessary to adequately prevent degradation of chlorine residuals by sunlight.

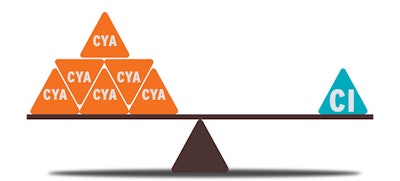

There are, however, those who now challenge the basic presumptions that chlorine, when used as the sole sanitizer, should be applied within a set concentration range. In a nutshell, the idea is that the proper chlorine concentration should be based on the level of cyanuric acid present in the water — the higher the CYA concentration, the higher the concentration of free available chlorine.

It's an idea that has received little exposure or discussion. Yet according to chemical consultant and author Robert Lowry, one the industry's most prominent authorities on water chemistry, the time has come to rethink the way the industry manages water chemistry.

Specifically, Lowry is recommending that FAC should be maintained at 7.5 percent of the CYA concentration, which ideally should not exceed 50 ppm.

FROM EXPERIENCE

There's no doubt this idea is a radical departure from pool professionals' basic understanding of water chemistry, but it comes from a qualified source.

Since joining the industry back in 1973, Lowry has started two chemical companies (Robarb and Leisure Time Chemicals), authored 12 books, co-founded Service Industry News and developed 111 products. He has worked as an independent consultant since 1995.

Lowry's seminars on water chemistry in pools and spas are widely considered the gold standard for water treatment education within the industry.

"I've always tried to share information with the industry that I believe to be true," he says. "Sometimes that means challenging our basic assumptions. The relationship between CYA and chlorine is one of those assumptions."

Lowry's re-examination of the CYA/chlorine relationship began as a result of his authorship of the Independent Pool and Spa Service Association's two chemical training manuals, which he wrote in 2006 and 2009 respectively.

"I received a correspondence from theoretical chemist Richard Falk," he recalls. "He told me that some of the information in the manual was incorrect, especially where CYA and chlorine are concerned."

Falk shared with Lowry a number of citations to support his critique. One of those came from an out-of-print book titled "The Chemistry of Water Supply, Treatment and Distribution" by Jay O'Brien (Ann Arbor Publishing, 1973).

A COMPELLING ARGUMENT

Falk pointed Lowry to a chapter about the equilibria of isocyanurates. "According to O'Brien, there was more chlorine tied up by CYA than I had previously believed," Lowry recalls. "I subsequently spoke with some of the chemists at Monsanto, which makes cyanuric acid, and also some of the companies that manufacture trichlor. These conversations confirmed the view that there is indeed an equilibrium relationship between chlorine and CYA."

(Lowry also cites chemist Ben Powell for first developing the 7.5 percent concept back in the '70s.)

"Based on existing information," Lowry explains, "I came to realize that at any given time, you only have 3 to 4 percent chlorine available to do anything. That led me to look at the level of chlorine we need to kill algae and bacteria."

Given that there are potentially hundreds of organism species in a swimming pool, Lowry began exploring which of those should be used as a standard for the necessary levels of FAC at a given concentration of CYA.

"Should we use as a standard E. Coli, Pseudomonas, Giardia, Cryptosporidium or some type of algae? When you look at the required chlorine concentration for various organisms, the differences are huge," he explains. "The basic idea is to determine how much chlorine we need to prevent growth. We don't need to kill everything's that in there, but instead prevent growth to the point that these organisms have no negative effect on bathers and water quality. Simply put, we need to kill algae faster than it can reproduce."

With that fundamental question in mind, Lowry lit on the simple answer: Because algae is tougher to kill than most forms of bacteria, maintaining enough chlorine available to prevent algae growth will ensure there is plenty to take care of bacteria in a residential pool. Public or commercial pools require enough chlorine to oxidize organics and accommodate larger numbers of people.

"I discovered that in order to stop the growth of algae, you need only .05 ppm of HOCl, which certainly doesn't sound like much," he says. "The problem is that in the presence of cyanuric acid at a concentration of 30 ppm, as an example, only 3 percent of chlorine is available to do anything. Under those conditions, a concentration of 3 ppm chlorine means that you only have .1 ppm available, but we also have to consider that at a pH of 7.5, only 50 percent of that concentration is available as HOCl, which brings us to .05."

(The amount of HOCl and OCl– is determined by the pH of the water and at a pH of 7.5 there is 53 percent in the HOCl form.)

SNOWBALLING CONDITIONER

The problem, he explains, is that when CYA levels increase, the percentage of available chlorine decreases; at 60 ppm CYA, 98 percent of chlorine is bound. [The bound chlorine never gets above 98.2 percent.] For pools treated with trichlor, the level of CYA increases rapidly and concentrations over 100 ppm are typical.

"For every 10 ppm of trichlor that you add, your increasing CYA by 6 ppm, so obviously the level is going to rise very quickly, which in turns binds larger percentages of chlorine," he explains. "If your chlorine demand is 1 ppm chlorine, that means every 10 days, your CYA concentration is going up by 6 ppm, and that's if the chlorine demand is only 1 ppm. If the demand is 2 ppm, which is very common, CYA levels increase at twice that rate."

In effect, he says, a homeowner or service technician may keep chlorine residuals at recommended concentrations but unbeknownst to them have inadequate FAC to be effective. All of which explains why water quality will decline even though the chlorine levels are kept in what we've been taught is the proper range.

(This phenomenon has often been loosely referred to as "chlorine lock" a largely inadequate term that betrays the fact that chlorine and CYA exist in a state of equilibrium.)

"At first, when the concentration of CYA is 20, 30 or zero, chlorine at a normal concentration will get the job done," Lowry explains. "But once you get in ranges above 50 ppm, which can happen within a few weeks, or less depending on the chlorine demand, you come to the point where you start to see algae and you're left wondering what's going wrong.

"While algae itself doesn't present a health hazard per se, common sense tells us that if you're not killing the algae, you also might not be killing the bacteria."

While at first blush, this concept of the CYA/chlorine equilibrium might seem to demonize CYA and chlorine products that contain it, Lowry is quick to point out that without CYA in the mix, it's nigh onto impossible to maintain chlorine residuals because of how quickly chlorine is destroyed by UV light.

"There's no question that in a chlorinated body of water exposed to sunlight, you need cyanuric acid," he says. "What the equilibrium equation tells us is simply that we need to think in terms of maintaining lower levels of CYA."

To that point, Lowry recommends rejiggering the standard to limit CYA concentrations to 50 ppm, meaning that when that level is reached it's helpful to switch to chlorine that doesn't contain CYA, sodium hypochlorite or calcium hypochlorite being the most commonly used.

And, at whatever the CYA concentration, FAC should be maintained at 7.5 percent of that concentration, i.e. at 100 ppm CYA, you need 7.5 ppm FAC.

"It turns out that's the only way we can be sure we have enough FAC to do the job," he concludes.

For a detailed discussion of this issue, check out Lowry's paper here.

|

|