Automatic pool covers make a pool safer, easier to maintain, more energy efficient and, some would argue, prettier. With all those advantages, why not put one on every pool. Well, not every pool owner is willing or able to incur the expense. Plus, every pool setting may not accommodate a cover. The site must allow for the mechanism that rolls and unrolls the cover, as well as the straight tracks on which traditional rectangular covers travel. The cover may not look rectangular on more advanced projects, but under whatever slick track-hiding trick is in play, there's usually a rectangular cover.

Not every covered pool employs recessed tracks, cantilevered decks or other means to hide the fact that the cover is rectangular. In fact, while cover manufacturers have gone to great lengths in working with creative builders to cover pools of myriad shapes, many auto pool covers simply glide along tracks installed on the deck.

What follows is a look at three auto cover installations: a basic tracks-on-deck job, a moderately difficult job, and one that employs a technique the builder calls "bridging."

BASIC

Straight, But Not Narrow

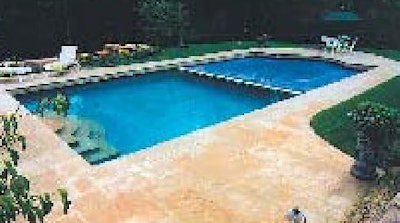

Even though this pool has two Roman ends, and the sloping site presented some challenges, it is considered a basic auto cover installation because the tracks are placed on the deck, running parallel to the long, straight sides of the pool. The cover mechanism is housed in the deck under an aluminum lid.

The designers at Performance Pool & Spa in Woodbury, Minn., took some steps to help the cover blend in with its surroundings, but the cover remains in plain sight at all times. Still, it's nice that the tan cover coordinates with the stamped-concrete deck, and the tracks themselves are not so visually different from the narrow white coping outlining the viny-lliner pool.

Also, as is standard practice at Performance Pool & Spa, the tracks run as close to the pool as possible. This minimizes the size of the cover and maximizes usable deck space when the pool is covered, explains salesman Brandon Eytcheson.

PERFORMANCE POOL & SPA

Woodbury, Minn.

Pool size: 18 feet wide, 40 feet long

While not completely hidden, the tan cover blends in with the stamped-concrete deck.

INTERMEDIATE

Graceful River Curves

What makes this cover job more challenging than most is the different surfaces each side of the cover travels over. The cover's left edge (away from the river) drags over the lower deck, while its right edge glides mostly over water, as its track follows the negative edge. With tracks in such vastly different environments, adjusting the tolerances for each side of the cover presented an unusual challenge, explains Steve Chandler, president of Custom Pools & Patio, Boise, Idaho.

The need to fine-tune the mechanism, coupled with its proximity to the Boise River, led Chandler to select the hydraulic mechanism unique to Aquamatic. "We just wanted to use the hydraulic mechanism for this job because it offers quite a bit of power and we found it to be more adjustable," he says.

Chandler notes that since this job was completed, other cover manufacturers have introduced completely sealed motors, which are also safe to use in wet environments.

Structurally, this job is like many deck-on-deck installations. That is, a lower deck surrounds the pool, butting up to its free-form shape, while the upper deck has a cut-out rectangle, designed to support the cover's tracks underneath. The box housing the cover has a masonry lid that blends with the stamped-concrete deck.

CUSTOM POOLS & PATIO

Boise, Idaho

Pool size: 15 feet wide, 36 feet long

Proximity to the Boise River influenced the decision to use a hydraulic drive mechanism, rather than an electric one, for this cover.

ADVANCED

Roman-End Recess

This pool might look simple to cover because it has two straight, long sides for the tracks to travel along. But note that the cover retracts into a Roman end. Pool builder Jeff Hammerschmidt, owner of Master Pools by High-Tech Pools in Cleveland, calls this technique bridging, because the deck forms a suspended bridge over the cover at one end.

HIGH-TECH POOLS

Cleveland

Pool size: 18 feet wide, 36 feet long

A structural concrete slab forms a bridge over this cover's housing, allowing it to recess into the pool's Roman end.

The bridge is a structurally engineered slab of concrete, anchored at each end (going across the Roman end), but suspended over both the cover mechanism and the wall the cover extends and retracts over. The bridge design adds about 6 to 8 inches of deck thickness, so the water level can be more than 1 foot below the deck.

Like all traditional cover jobs, the cover is housed in a rectangular box. Unlike most projects, however, the wall shared by the cover's box and the pool is not simply straight. From the pool side, the wall has a Roman end. Toward the long walls of the pool, the wall is more than 3 feet thick to accommodate the curve on the pool side and create the straight wall of the cover's box. The wall underneath the bridge is topped with tile, so the cover has a smooth surface to extend and retract over.

"It also looks nice if you're looking under the bridge from the water level," Hammerschmidt notes. The top of the beam over which the cover extends and retracts is 2 inches lower than standard pool beams, where the track is typically located. This is common for under-deck track mounts.

Meanwhile, the tracks extend out from under the bridge. To install them, High-Tech crews leave holes under the stone until the track is mounted. After the tracks are installed, the holes are filled with grout and covered with the deck material. On this job, Hammerschmidt recalls that only 4inch holes were required — just big enough to fit a hand in and attach the ends of the track. Larger holes would be required for more-complicated bridge shapes.

This technique works best with stone decks, Hammerschmidt explains, because one can control the joints and gain more strength. Plain concrete doesn't work as well. It's also best for pools that are no more than about 20 feet wide (from track to track).

Try This At Home

There are lots of other tricks to hiding cover tracks and covering pools that aren't rectilinear. The pool can be completely framed by a raised deck that has a rectangular opening.

This technique, sometimes called deck-on-deck, gives the cover the rectangle it needs while allowing the pool to be virtually any shape.

Another approach is to cantilever a significant part of the deck on one or both sides, with cover tracks placed underneath. In addition, cover lids — even when they're mounted flush with the deck — can be camouflaged with masonry tops or a coating. Some builders, in search of ways to cover even-more-complex pools, will use more than one cover. Thanks to innovation on the part of both builders and manufacturers, almost any style pool can accommodate an aesthetically pleasing automatic pool cover.

GERMAN ENGINEERING: Covert cover fits right in

The owner of this pool wanted to swim year-round. In northern Ohio. Plus, the pool is on a cliff, has a long negative edge, and simply could not be altered to accommodate a traditional cover's straight tracks.

So seasoned Master Pools builder Jeff Hammerschmidt, owner of High-Tech Pools in Cleveland, was reluctantly considering a 1.5 million-Btu heater, knowing that only such an enormous heater would keep the 1,075-square-foot pool warm during a Snow Belt winter.

But then Hammerschmidt visited Interbad, an inspiring pool/bath/physiotherapy trade show in Germany, where he saw a pool cover unlike any he'd ever seen before. It can roll down into the floor of the pool and be cut to virtually any shape. It's not a safety cover because it doesn't attach to the sides of the pool, but the slats that comprise it will hold a person. "Your feet will get wet because water will come up through the slats, but it's strong enough to walk on," Hammerschmidt says.

This type of cover, now available in the United States from Aquamatic, is made of 2-inch wide, hollow plastic strips, which are custom cut and then sealed and hinged together. Like traditional covers, these also roll up into a basin or trough. The basin can be located in the pool floor, or under the deck, sharing a wall with the pool.

The cover is released from its housing by the push of a button. The cover unrolls, floating into place. Another push of the button would allow the cover movement to stop if desired for maintenance.

"The niche for this product is the free-form pool," Hammerschmidt says, adding that he decided not to install one on his own pool because he couldn't justify the cost, personally. The cover shown here cost the customer more than $55,000.

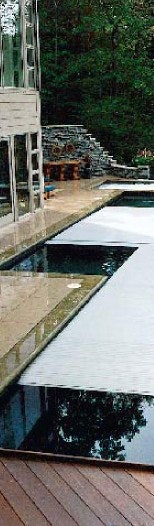

Ready . . .

This pool is about to be covered. A button has been pushed, opening the lid of the trough. The trough, located under the pool floor, houses the cover when it's not in use. The dark line across the floor of the pool is the shadow cast by the open lid. When the lid is closed, it is completely camouflaged. It can be surfaced with whatever the pool floor is made of — in this case, tile.

Set . . .

Having been released from its trough in the pool floor, the cover, comprising a series of custom-cut plastic slats, unrolls and floats into place. The drum on which the stored cover rolls up turns a programed number of times to fully release the cover. The mechanism that turns the drum is concealed in a vault that shares a wall with the pool. Terraced landscaping hides the vault while allowing service access.

Done.

The German cover's hard plastic slats don't wrinkle like traditional vinyl covers — an aesthetic improvement.

Although shown here in white, the covers are available in many colors.

—E.S.P.