Earlier this year, The Pool & Hot Tub Alliance announced the publication of its updated ANSI/ APSP/ICC-16 2017 American National Standard for Suction Outlet Fitting Assemblies for Use in Pools, Spas and Hot Tubs. Approved by the U.S. Consumer Product Safety Commission, the revised law will take effect on November 24, 2020.

This update to a standard best known for its impact in the VGB era will have a significant effect on the aquatics industry and improve swimmer safety.

As industry veterans of more than 10 years will remember, the Virginia Graeme Baker Pool and Spa Safety Act was passed in 2007, requiring all new and existing public pools and spas to be equipped with compliant suction outlet fitting assemblies (referred to in the text of the law as “Drain Covers”).

“The VGB Act is named after Virginia Graeme Baker, a young girl who, while playing in a residential spa, sat on a flat-and-flush mount, 8-inch round drain that was easily sealed by her little hip,” says Steve Barnes, PHTA Technical Committee and PHTA-16 Standard Writing Committee chair. Barnes, who is also director of science and compliance for AquaStar Pool Products, points out that the spa drain was the sole source of water for the pump. “So, when it was too easily blocked, the large suction forces held her underwater, causing her to drown.”

In addition to Virginia’s tragic death, there were another 12 suction system injuries in 2002. This was followed by 32 additional injuries and four more fatalities over the next five years, leading the U.S. Congress to take federal action.

“Historically, the number of suction entrapment incidents are very low compared to all other drowning hazards, yet they are different because they are 100% preventable,” Barnes explains. After decades of research, a team of cross-functional experts, including representatives from the Consumer Product Safety Commission, devised several tests to prevent further entrapments. “The key requirements of the VGB Act mandate the use of certified drain covers that are properly installed while also making sure the system design does not allow a swimmer to fully block the flow of water to the pump,” Barnes states. He says for new projects, this is accomplished in one of two ways: by using covers too large to seal (which are classified as “unblockable”) or by using more than one of the smaller drains.

REGULATING SAFETY FEATURES

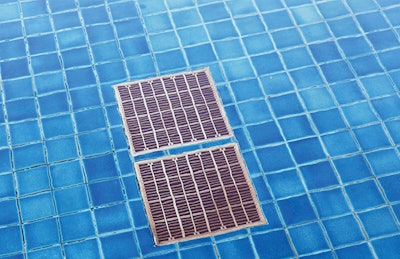

ANSI/APSP/ICC-16 2017 Standard for Suction Outlet Fitting Assemblies for Use in Pools, Spas and Hot Tubs was written to regulate drain cover safety features and improve anti-entrapment tests. “Certified products undergo UV Exposure testing followed by dozens of mechanical strength tests,” Barnes says. “Other tests include checking openings to address finger and limb entrapment.”

Although the standard dates back to 1987, the first version was voluntary and did not include a test to address body entrapment. “That wasn’t added until the 2007 edition, the version adopted into federal law, and it is no longer optional,” he adds. “The body block test is based on the size of a large man’s back (18 inches x 23 inches specifically), and anything smaller can’t pass the test if it doesn’t stick up enough.”

Barnes acknowledges that there is a trade-off for improving body entrapment safety. Because covers 18 x 18 inches and smaller must stick up a couple of inches, they can get in the way of feet and also trap some automatic pool cleaners. While inconvenient at times, these revised safety regulations will undoubtedly save lives.

“Drain covers keep swimmers away from the pump’s suction, and because swimmers don’t know dangers lurking behind the curious-looking objects under the water, the product design and testing must be thorough enough to address all hazards all the time,” stresses Barnes.

UNDERSTANDING ENTRAPMENT HISTORY

In seeking to understand the problem, the PHTA Technical Committee reviewed suction entrapment-related reports to identify the root causes of these incidents. Between 1985 and 2002, 51 hair entrapments were responsible for 36% of the 141 pool and spa entrapments reported by the CPSC. With the elimination of body, limb and evisceration incidents in 2007, the percentage of hair entrapments skyrocketed to 60%, according to the latest CPSC report.

In response, Barnes says the 2017 update greatly expands the number of tests required to address hair entrapment. “Hair is the one hazard manufacturers and government regulations can’t solve without the help of designers and the installation of products certified for the actual operating flow of the pump,” Barnes explains. “Because hair flows with the water, it can be drawn through drain cover openings, traveling 16 inches into the suction piping, after which it must be pulled free. Because hair is so small, it isn’t possible to transfer water to the pump without bringing hair along for the ride, so the standard limits the removal force to five pounds of pull.”

This test is performed while the pump is running at full speed. “Five pounds sounds like a lot to some people, and not much to others,” he remarks. “To help put it in perspective, just a few hairs tangled behind the cover causes a product to fail the test. When this happens, it must be tested again at a lower flow rate.”

The new testing process, he says, will result in a pipe-size-specific flow rating driven by the depth of the suction pipe. “Generally speaking, the deeper the suction pipe, the higher the flow rating. While shallow pipe connections are more convenient for designers and installers, they have lower flow ratings for the same size pipe because more hair gets inside,” he describes.

IN-DEPTH INSTRUCTIONS

Barnes points out another significant improvement to the drain cover standard: highly detailed instructions. “They now require manufacturers to address all aspects of the product life-cycle: design, installation, maintenance, repair, winterizing, even what to do with stripped out fasteners,” he says. “Following over a decade of sophisticated testing, it is now well documented that traditional pool engineering experience and even hydraulic calculations cannot predict if and when hair might tangle. Therefore, professional engineers and other registered design professionals are prohibited from performing this type of work on manufactured products that are listed by an International Organization for Standardization 17065 certification agency.”

Historically, he says best practices have not been adequate enough to address all hazards, all the time. “Going forward, designers, installers and inspectors should be referring to product specific instructions for minimum sump depths, and all other design elements,” he emphasizes. “In short, drain cover certifications should be treated like pumps certified to NSF 50 and UL 1081, which address all regulatory requirements, leaving nothing for engineers and inspectors to figure out. Look for the certification documentation and follow the installation instructions.”

“To be clear,” Barnes adds, “this restriction does not change the important role registered design professionals play in designing all aspects of commercial water park-type drain covers. They are called Registered Design Professional Suction Outlet Fitting Assemblies, and they are always significantly larger than the 18 x 23 inches.”

THE BOTTOM LINE

Under the VGBA, drain covers manufactured on or after November 24, 2020 will be required to comply with this new standard. In the meantime, products certified to one of the prior versions of the standard will continue to be compliant until they expire, or the product is damaged or degraded in any way.

“It is important to understand this is a rolling change that impacts manufacturers and registered design professionals who design and certify custom, water park-type suction systems,” Barnes explains. “It only applies to products manufactured after the effective date. As for products being produced in full compliance with the 2007 standard, if they are properly certified and include the minimum documentation, such as flow rating, fasteners and sump depth specifications, they are allowed to be installed and used after the deadline. This is very important: Qualifying products can sit on shelves throughout the product supply chain and still be installed in the future. Likewise, for products currently installed.”

He says as long as the product was properly installed, isn’t cracked or broken, and is within its installed lifespan, the pool remains compliant and can stay open to users.

For more information on all of PHTA membership categories, including dues and benefits, visit PHTA.org.