Marble and limestone have been used for centuries to create some of the most amazing pieces of architecture known to humankind. A limestone aqueduct built by the Assyrians around 691 B.C. brought fresh water to the city of Nineveh. Ancient Greeks used marble and limestone to build the Parthenon and many other structures at the Acropolis in Athens. The Romans also used these materials in the construction of their world famous baths.

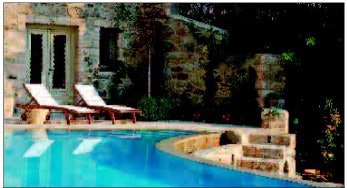

On a smaller scale, homeowners today are using these beautiful and durable natural stones to outfit their poolscapes. In the past, using the stones — especially on applications with curvilinear shapes — was often cost-prohibitive; but advances in cutting machinery have enabled Harris Brothers Natural Stone Importers to offer marble and limestone coping, grates and deck material — including complex shapes — at a competitive price. Owned by Tim and Steve Harris, the company, which exhibited in the Genesis 3 Pavilion at the AQUA Show last November, imports the stones from a factory run by Sofikitis Marble Limited in Athens.

"We send detailed scale drawings to the individuals running the machinery at the factory in Greece, and they can cut the material to within millimeters," says Steve. "The calibrated machinery reads the CAD drawings by computer and then it's programmed through the saw, which cuts out the shape supplied by the CAD drawings. So we have the ability to produce any desired shape as far as coping goes.

"And it's fairly simple to install. With the product cut to a pre-formed shape, the application is very simple." Best of all, says Tim Harris, "It's the real thing. It's not concrete colored to look like stone."

For the more-custom application, adds Steve, these products definitely satisfy the most discriminating client. Though the new technology makes these materials accessible to skilled builders, there are still some guidelines to keep in mind.

1. PERIMETER-OVERFLOW APPLICATION

When using natural stone coping and grates on a perimeter-overflow edge, precision is key.

"The bond beam needs to be as close to perfect and level as possible," says Steve. "When water is standing still, it will sit perfectly level. With that in mind, a deck-level or perimeter-over.ow pool must be pre-formed as close to perfect as possible to simplify installation. If the forms are poured out of level, trying to make the material sitting on top level is extremely difficult."

Final adjustments can be made, says Tim, but installation is significantly simplified if the substrate is level.

In general, with perimeter-over.ow pools, if the edges are not perfectly level all the way around the pool, water won't flow over the slot as it should in some places.

"Laser sighting to install coping is highly recommended, to be sure the bond beam is level, Steve says. In this process, a laser sends a beam around the perimeter of the pool and lets the installer know whether it's level all the way around.

The perimeter-over.ow edge effect is enhanced, says Tim, when both the coping and grates are made of natural stone. "When the grates and coping are produced in the same material, you have this look that continues from the coping right on through to the decking," he says. "You're not changing into a plastic grate that'll have to be replaced in two years. It's not out of galvanized gutter material or a stainless steel. It's the same product, so the edge just fades away and you don't see this other grid made out of another product."

Tim adds that the natural stone grates can be removed to clean out the channel at any point around a pool.

2. REMODELING

These natural stone products can also be used on a traditional skimmer-type pool, says Tim.

"Say, for instance, you want to give your pool a face-lift and you have brick around the edge," he says. "That can all be removed and then the installer would achieve a level surface around that beam area where the existing brick was by re-floating cement on top of that to make it level. Then he'd thinset a new coping piece and adjust that height to match the existing pool deck. Or if you're going to change your pool deck as well, that would be torn out and then formed up to match the height of the new coping."

If your client doesn't want to rip out the existing material, Harris Brothers has a solution for that, too. "Let's just say you've got brick there now and you want to cover it up and you want to cover your deck without tearing all that out," says Tim. "You can literally thinset this coping on the existing brick or concrete coping. So you can remodel a pool without getting into a major expense and tearing everything out."

3. WATER CHEMISTRY

A pool out of balance is never a good thing, but a pool with natural stone coping and grates that's out of balance is particularly bad. "Correct pH balance must be maintained when using natural stone," says Tim.

"If acidic levels do get out of hand, the water can have a tendency to discolor the stone or actually start to erode it," says Steve.

To protect the stone in case pH levels do get low, Steve recommends applying a penetrating, protective sealer on the entire surface.

4. EXPERIENCE NECESSARY

If you've never worked with natural stone before, plan to learn a bit about installing it before jumping into a project where it's specified.

"This is not for the beginner pool builder or pool contractor," says Steve. "The pool contractor that will install this product has the .air and the experience and the knowledge to complete a top-shelf, high-end product."