The winterizing process is different for just about everyone. It can differ based on your geographic location, which can dictate when winterizing season begins, the types of pools you'll service, the maintenance required during the off-season and more.

However you manage the winterizing process in your area, the goal is the same for everyone: protecting pools from damage to the equipment, interior finish, plumbing, tile and structure that can result from freezing temperatures.

Here, we review the key steps to keep in mind when winterizing an inground pool. They largely apply to those in severe winter areas, but much of this advice is universal.

WATER TREATMENT

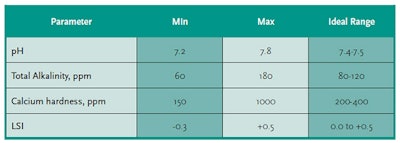

As a starting point, most winterizing processes recommend balancing the pool water to APSP standards. (See table below.) Consideration should be given to the fact that as the water temperature decreases, the Langelier Saturation Index will decrease, meaning the water will become more corrosive. This balancing process should take place 3-7 days prior to closing the pool. These levels should be adjusted and then rechecked using proper testing equipment.

At initial closing, it may be preferable to balance the water in a positive LSI range, giving you a cushion since LSI drifts downwards as the temperature drops.

For chlorine and bromine pools, pool water should be shocked using a chlorine product to remove residual swimmer waste, kill bacteria/algae and remove other organic contaminants from the water. Additional oxidation may be performed with a non-chlorine oxidizer. Chlorine and other oxidizer residuals should be allowed to decline prior to adding additional closing chemicals such as algaecides and sequestering agents that may be degraded by high levels of oxidizer.

For PHMB (biguanide) sanitized pools, the pool water should be oxidized with hydrogen peroxide.

The use of an EPA-registered algaecide is recommended due to the lack of winter filtration as well as the use of certain covers that may allow sunlight and fine organic debris/contaminants to enter the pool water.

Related: Closing By The Temperature

Balancing the water is the first step in preventing staining to interior finishes; however, the use of an appropriate stain preventative is recommended in many regions due to the length of time the pool is shut down. Many commercially available winterizing kits will contain sequestering or chelating agents. Always check with the individual manufacturer of the winterizing kit as to the best practice for use during the pool closing process.

Clean the pool. This should include a thorough brushing of all the surfaces, including, but not limited to, walls, coves and floor. Skim the surface to remove any floating leaves and other organic debris. Vacuum the pool.

After taking care of the water treatment, you can move on to the following procedures. These steps are not listed in order; the order will vary according to the location and type of equipment used.

EQUIPMENT

Clean the filter. Backwash several times if working with a sand or D.E. filter. If the pool has a cartridge filter, remove and clean the cartridge(s), allow them to dry and then store for the winter in a warm, dry, indoor location. D.E. grids can also be cleaned, removed and stored indoors.

Empty all chemical feeders (see Precautions section for more). Drain the pump, filter, heater and chlorinating equipment. Place the drain plugs in the hair-and-lint (pump) basket so you can find them in the spring.

Using an appropriate method, purge any remaining water from the pump, heater, heat pumps, chemical feeder and other wetted equipment. Care must be taken to use the proper procedures and equipment (e.g. wet/dry shop vacuum, low-pressure air compressor, etc.) since pool equipment and lines cannot take excessive pressure, and overpressure could present a safety hazard. This process should only be performed by an appropriately trained professional familiar with the potential hazards associated with pressurized air.

If the pool has an electrolytic chlorine generator, make sure there is no standing water in the cell. Remove the cell and store indoors.

If the pool utilizes automated controllers and chemical feed equipment, be sure the electrical power to the controller is disconnected. Remove any sensors from the flow cells, then clean and store them in accordance to the manufacturer's instructions. Empty the flow cells, then clean and allow them to dry before storage.

RELATED: Products to Beat the Winter Blues

If the pool utilizes a UV generator, follow the manufacturer's instructions and drain and remove the lamp and quartz sleeve. Store them in a warm and dry location.

If either an ozone generator or mineral ionizer system is used, winterize in accordance with manufacturer's instructions.

If peristaltic pumps are used, properly drain the system, remove any feed and injection tubes, then clean and allow to dry before storage. Make sure chemical storage tanks are empty. Store any unused chemicals as directed by label directions and state and local codes.

Automatic controllers that are installed outdoors should be removed and stored indoors or protected from the extreme effects of winter.

Many equipment manufacturers have specific instructions for safeguarding their equipment. Always check with the manufacturer if you have any questions. Make sure the circuit breakers are in the off position prior to disconnecting electrical power to any equipment. In severe snow areas, the motors should be removed from the pump housing and stored indoors in a dry location. If a motor is left outdoors, make sure it has a weatherproof protective cover.

Turn off the pilot flame if applicable, main gas valve and gas supply to the gas heater. Drain any water from the heat exchanger in accordance with manufacturer directions.

PLUMBING

Water that remains in the plumbing lines and freezes can cause significant damage. You can prevent this by completely purging water from the lines using an air compressor or the discharge side of a shop vacuum. Blow air through the lines until bubbles appear inside the pool. This includes all return lines and suction lines (skimmer and main drain), as well as lines to water features, solar heating, pool cleaners and slides. Again, caution is advised when using pressurized air.

When the lines are clear of water, remove the wall fittings and insert tapered, expandable plugs into the return lines. Tighten in place. In some locations, severe freezing water may dictate the use of straight pressure plugs.

Suction outlet (main drain) lines should have air blown through them until bubbles appear in the pool. Then plug the pipe topside or close the valve to the suction outlet. This will create an air lock in the line, preventing water from re-entering the lines.

Skimmer lines must be purged with air. Once bubbles appear, screw in a threaded expansion plug into the skimmer. These devices will prevent freezing water from expanding and cracking the skimmer. Use an appropriate (e.g. PTFE) plumbing tape on the threaded fitting to ensure a watertight seal.

Some APSP pool professionals say adding antifreeze to plumbing lines is not necessary if they are purged with air. If you opt to use antifreeze, you can mix a solution of 1 part propylene glycol to 2 parts water or use antifreeze specifically intended for swimming pool use (see precautions section for more info). This solution should protect any residual water from freezing down to 10 degrees Fahrenheit (or -12 degrees Celsius).

LOWERING THE WATER LEVEL

The issue of draining water — in particular, how much to drain — is often based on regional climate and the type of cover (solid or mesh) used on the pool. Expected rain, snow and snow melt levels will often influence how much water is drained. Consult with your winter cover manufacturer for their specifications.

Surface water that freezes can damage waterline tiles, prematurely dry out vinyl liners and expose plaster surfaces to the atmosphere, which can create cracked and defined water line indications on the surface. These are the suggested drain-down levels for each kind of pool as per APSP's Service Tech Manual, 4th Edition:

1. Vinyl lined:

1 inch (25 mm) below skimmer mouth or tile line, whichever is lower.

2. Plaster finishes with solid material cover:

1-6 inches (25-152 mm) below the skimmer mouth or tile line, whichever is lower.

3. Painted or natural finish with solid material cover:

6 inches (152 mm) below skimmer mouth.

4. With no cover or mesh cover:

18-24 inches (457-610 mm) below skimmer mouth.

5. With automatic cover:

Water should be no lower than the bottom of the skimmer mouth.

APSP pool professionals suggest that the less water drained from the pool, the less damage there will be to liners, plaster and other cementitious finishes from prolonged atmosphere exposure. Higher water levels also mean less stress on covers. However, water levels should not be allowed to rise above the tile line of the pool to prevent damage to those surfaces during the winter.

COVERS

Prior to installing winter covers, ladders, diving boards and handrails should be removed, cleaned and stored in a dry place. Remove organic debris (leaves, etc.) from the pool prior to installing the cover. As discussed in APSP's Service Tech Manual, 4th Edition, the four main types of winterizing covers include:

1. Solid lightweight fabric cover:

Constructed of a solid film or sheet of synthetic fabric, held down by water tubes, sandbags or ropes and anchors.

2. Spring-loaded ASTM mesh safety cover:

Made of mesh fabric, usually anchored to the pool deck.

3. Spring-loaded ASTM solid safety cover:

Made from reinforced vinyl fabric, usually anchored to the pool deck.

4. Automatic and manual safety covers with tracks:

Made of solid fabric; available in standard and custom sizes.

All covers, regardless of type, have advantages and disadvantages. The type of cover and the level of the water in the pool must be closely monitored over the winter season to prevent problems such as over-filling.

To avoid a safety hazard, solid covers should have automatic cover pumps that remove water from rain or melted snow (see Precautions for more).

RELATED: Winter Cover Notes

Leaves and other organic debris must be periodically removed from the top of all covers to prevent the cover pump from clogging or damaging the cover.

Tracked (automatic) solid covers must be monitored for accumulation of water, snow and ice. Excess weight from these items can damage the track system, possibly damaging the concrete, coping or pool wall.

With all winterizing covers, the long-term durability and longevity of the cover is dependent on proper water balance, proper water levels under the cover, regular maintenance and cleaning.

PRECAUTIONS

As with all chemical applications to pool water, proper safety considerations must be followed.

Do not mix chemicals. Follow manufacturer directions for the proper use of chemicals, including the correct time to add winterizing chemicals to avoid damaging surfaces, covers and equipment.

When cleaning out chemical feeders, exercise caution and wear the proper personal protective equipment such as gloves and safety goggles. Check with the product manufacturer regarding disposal of chemicals from feeders.

Properly shut down and clean filters according to manufacturer directions. If an acid cleaning solution is used, rinse thoroughly with water to remove any acid residue and allow to dry completely before storage.

If anchoring pool covers with water tubes, avoid overfilling — too much water can cause the tubes to split during freezing weather. Do not use masonry blocks, bricks or concrete stepping pads to hold down covers as they could fall into the pool and damage the interior finish.

RELATED: With Winter Pool Covers, End With the Start in Mind

Never use ethylene-glycol-based (common automotive) antifreeze in winterizing pool equipment and plumbing lines. Always use a pool formula antifreeze or a propylene-glycol-based product. Antifreeze should be used sparingly to avoid problems when opening the pool in the spring.

All solid safety covers must meet ASTM F1346-91 Standard Performance Specification for Safety Covers and Labeling Requirements for All Covers for Swimming Pools, Spas and Hot Tubs and have an automatic means of preventing water accumulation on top of the cover whenever the pool is covered. For example, this may be accomplished with a drain panel or a pump. Rainwater on the cover is a drowning hazard for children. Consumers must be made aware of the necessity of preventing water accumulation on top of the cover.

Only cover a pool when the water analysis indicates the chemical parameters are within the cover manufacturer's recommended ranges.

Finally, after adding winterizing chemicals, follow label instructions and local code requirements for the disposal of any remaining chemicals.

The degree of complexity associated with winterizing an inground pool is dependent on many factors. From an environmental or climatic perspective, the expected temperature range, the amount of precipitation and the depth of the frost line will all dictate what steps must be taken to avoid damaging the tile, interior surfaces, plumbing, equipment and structures. One should consult with the various chemical manufacturers, pool manufacturer or builder, equipment manufacturers and cover manufacturers for the correct procedures and processes to use in a geographic region.