Wood materials have been dominant players in the spa industry for the better part of its existence. Makers of spa steps, surrounds and most accessories followed the trend. But as as the category grows and evolves, new materials are appearing in the marketplace, allowing retailers and consumers to pick and choose the materials they prefer. Synthetic spa steps, surrounds and accessories offer homeowners the advantage of spending less time, money and energy updating their purchases and more of their time enjoying them, some manufacturers say. Others say consumers will always enjoy the authenticity of wood products. It is up to you, the retailer, to determine what will fit your customers' lifestyles best. And there are plenty of exceptional products — whether wood or synthetic — to choose from.

Stepping Into The Spotlight

Mike Genova, president of Leisure Concepts, Spokane, Wash., says his company produced wood steps and accessories up until five years ago, but has since switched exclusively to polypropylene products.

"We saw no future in wood. We saw all the future in plastic. It's a better product. It's lighter, it's smarter, it lasts longer and the supply is endless," he says. "Wood is the way we used to do it as an industry. It's not the best way, it's just the way that we started doing it and we just never deviated."

Although synthetic materials are by no means surpassing sales of wood accessories, the industry is growing large enough to accommodate both. Some say there is a declining popularity in wood accessories, however, due to a number of factors. A dwindling supply of forest products available to manufacturers, price competition and inconvenience are hindering not only sales, but production as well.

"The ability to build wood steps is getting harder and harder," Genova says. "That's one of the biggest reasons why synthetic skirts on spas have come around."

Marc Jenson, marketing manager for Byron Originals, Ida Grove, Iowa, a company that produces the synthetic Step-N-Stow, agrees with Genova. "There are just so many advantages over wood," he says. "I think wood has still got the aesthetics, but it's becoming a little harder to get in certain areas, it's expensive and the main thing is the maintenance."

Synthetic spa products are most often made with polypropylene or high-density polyethylene materials, allowing for impact resistance and longevity. Manufacturers say users must only hose them off from time to time for cleanliness. The majority are also UV-stabilized and can sit in the sun without becoming brittle or fading. These attitudes could turn many would-be wood owners on to man-made materials.

Wood, on the other hand, must be re-stained periodically, which manufacturers say may interfere with a potential sale.

"People that get into these situations (buying wood products) have to spend $8,000 to $10,000 for a spa and realize, 'Oh, I'm back to stain this thing,' every couple of years," says Alan Robbins, president of the Akron, Ohio-based California Design Group, a division of the Plastic Lumber Company.

In addition, wooden steps and surrounds must also be cleaned to avoid a mold or tannin problem, which takes time and energy — especially if homeowners confront the problem too late.

"It is important, because the dust that builds up, when it gets moist, it becomes a breeding ground for fungus," says Michael Hunter, owner of the Ukiah, Calif.-based Sylvan Woods. He says this contributes to the black staining that a homeowner can get on redwood.

"The other issue with redwood is tannin, which is a substance in the wood, and it can be brought to the surface and also leave black marks," he says.

In an effort to minimize the amount of maintenance a homeowner must perform, however, some manufacturers are adding options to their lines, making wood components easier to care for. Sylvan Woods, for example, is now offering a product called Plastique, an invisible application that combines with the company's stains to help weatherproof the product and maintain its color. The stain does not, however, prevent the wood from cracking, which means a homeowner must still maintain it from time to time with cleaning and re-staining.

Availability And Cost

Besides the inconvenience of maintaining wood products, many manufacturers say vastly increasing shipping costs have slowed the amount of wood merchandise being transported across the country.

"Wood steps are heavy, so it costs a lot to ship them from California to Michigan," says Genova. "I would say from a manufacturer's point of view, it's very simple to ship plastic steps wherever in the country."

Genova also said he sees more wood steps sold on the West Coast rather than the East Coast because of the abundance of redwood in that area.

"It's just more available in those areas," he says. "And therefore the mentality of the people is that wood is kind of the hot ticket. And then of course you look in the Midwest, and it's not as practical."

Jenson of Byron Originals agrees: "I think when you look at every one of the areas, there might be some regional effects now where lumber is more plentiful, but when you look at the different regions of the United States, each one of those regions has its own reason for wanting something that's maintenance free. The northwest is wet — wood rots; the south, southwest, you've got dry, hot sun — that'll dry wood out; the southeast you've got hot and wet; and in the northeast you've got extreme cold weather."

But wood alternatives haven't always had it easy, and did not always sell as well as they do now. In the past, manufacturers say many maintenance-free products were poorly made, causing many retailers in the industry to shy away from selling them to their customers.

"The steps themselves are not flimsy, but they appear to be when you stand on them," says Hunter. "They rock from side to side, you stand in the middle of the tread and it sags a little bit.

"If you stand on a typical wooden step, it doesn't move anywhere. It's nice and solid. So it's an appearance of weakness even though I know they're quite solid."

This same mind-set is why many retailers and consumers, both in the past and present, are leery about purchasing a non-wood product. And it's hard to compete with a product that's been around for decades.

"We're selling a lot of wood products," says Christine Brandon, co-owner of A & B Accessories in West Fork, Ariz. "I think a lot of people really prefer wood products. We are in competition now with plastic somewhat, but a lot of our customers don't like the appearance of plastic. They like the integrity of the wood — they like the real thing.

"A lot of people have expressed dissatisfaction with the plastic steps. Some say that they're not constructed as well and that the appearance is really just not aesthetically pleasing to them."

Selling Strategies

While some customers will always prefer wood, others appreciate how easy it is to take care of plastic accessories. And if maintenance-free really is the next big thing, it is important retailers know how to sell it.

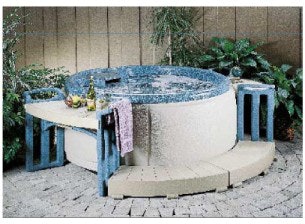

"Just getting it onto the showroom floor in a featured position gives you quite a bit of impact," says Robbins. "If it matches an acrylic liner and is a good color-contrasting match to their new spa siding, it just pops. I mean, it looks really nice and adds a new dimension to the look of their product."

Robbins also says sales can improve if a retailer sells the items in a package form rather than a la carte.

Many customers, Genova adds, don't know what they do or don't need when purchasing a spa. He says the biggest mistake retailers can make when trying to make a sale is to not offer any additional materials at that time.

"Retailers don't take advantage of the fact that the consumer's excited about their new purchase, and they don't turn that enthusiasm and excitement into purchasing additional items when they could," he says. "They rely on it to take place at a later time, and guess what. It doesn't happen."

In order to add that additional surround, step or accessory item, Robbins has some suggestions.

"No. 1 priority is to sell the products for a profit. It's very common for spa dealers in this industry to give things away. We don't believe that that necessarily has to be the case. No. 2 is creating demand for the product. Sell it. No. 3 would be to have it on display. No. 4 is to have it available in terms of inventory," he says.

Design merchandiser Kathy Roberts, from Cal Spas, Pomona, Calif., concurs. "It's all about displaying," she says. "It's all about picking the right colors to go around the right spa and making sure that it's an environment such that when the consumer walks into the retail store, they say, 'I want that in my backyard. I think it'll look great.' And if you don't show it, you'll never sell it."

Looking Forward

Although it is clear that sales of wood steps, surrounds and accessories are still strong, many manufacturers see the popularity of synthetic products growing — mainly because they are maintenance-free, durable and can last as long as the spa.

"The drawbacks to a plastic step have been that they're weak, bouncy and cheap-looking," says Genova. "I think dealers think that it doesn't look like wood. Well, it's never been intended to.

"That's what has slowed down the advancement of plastic steps, surrounds and spa skirts. Dealers continued to want it to look like wood, or they thought that the consumer wanted it to look like wood. And they're realizing that the consumer doesn't want the spa to look like wood. They want it to look nice, not cheap, and what they really want is no maintenance, no hassle and no problems. Things are getting better."