Yesterday, July 19, long-awaited pool pump regulations from the DOE went into effect. The subject of trade magazine articles for years, and called by some "the biggest regulatory change the pool industry has ever seen," the new rules ended production of most single-speed pool pumps in the inground residential market.

Existing inventories of non-compliant single-speed and two-speed pumps will remain legal and acceptable for use until exhausted. That is, those pumps will stay in the distribution chain and can still be used, but manufacturers will not make any more. Over time, those pumps will wear out and be thrown into the landfill of history, to be replaced by more efficient, compliant pumps.

Determining which pumps will be part of the industry's future (compliant pumps) and which will not (non-compliant pumps) is mostly a problem for manufacturers. The important actions, initially, fall to them. They will test and determine which pumps are legal, shut down lines of non-compliant pumps and raise production levels of compliant ones as quickly as possible.

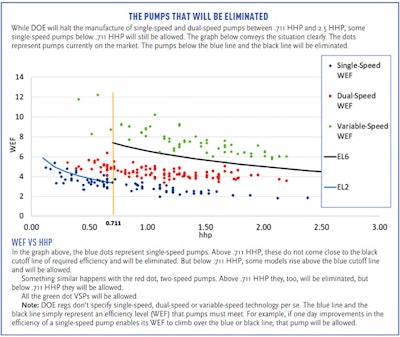

For retailers, service pros and builders, the apparent change will be relatively passive. Many types of pumps, especially single-speed pumps and most two-speed pumps in a hydraulic horsepower range from .71 to 2.5, will start to disappear from distributors' shelves, never to be seen there again. After that, in that hp range, there will be only variable-speed options.

For those industry members not used to selling and installing variable-speed pumps, there will be an adjustment period.

MOTORS

In a related development, as the federal DOE regulations take effect for pumps, California will implement legislation covering replacement pool pump motors.

RELATED: How to Sell Variable Speed

Like a car has an engine that turns gas into power that turns the wheels, a pump has a motor that turns electricity into power that spins the impeller. From the beginning of the DOE process, it was understood that if there were no regulations covering motors, then people could circumvent the DOE regs by simply replacing the burnt out motor on a non-compliant single-speed pump, same as you would a dead engine in a car, and then drive on.

Such a regulation covering pool pump motors has been discussed for years, and people involved with the process believe that a federal-level mandate covering motors is in the offing. In the meantime, California has written into its Title 20 regulations a new section covering replacement motors. This new rule parallels, in effect, the DOE pump regulations, but affects motors — it takes effect on the same day, does not affect existing inventories, and roughly mirrors the horsepower/efficiency criteria used in DOE.

Although it only affects California, it should be considered a harbinger of a national regulation to come that will govern the single-speed and dual-speed motors of non-compliant pumps.

NEW TERMS – WEF

The world of pumps has changed dramatically with the new regulations, and not just in the determination of which pumps will be scrapped. There will be new words to categorize and describe pumps, starting with WEF.

WEF is an acronym for "Weighted Energy Factor," which is a measurement of the performance of a pump in terms of gallons of water pumped per watt-hour. It's an efficiency rating, much like the miles per gallon (MPG) rating you see on the window of a new car at a dealership. In the same way MPG gives you an idea of how efficiently a car uses gas, WEF tells you how efficiently a pump uses electricity.

The rating tries to take into account the fact that VSPs and two-speed pumps achieve different efficiencies at different speeds. When a VSP is used for say, cleaning, at full speed, it is much less efficient than it is at low filtration speed. Since these pumps are used mostly for filtration, WEF is "weighted" at 80% of the low speed efficiency and 20% of high speed efficiency.

RELATED: The New DOE Pump Regs: Introducing Hydraulic Horsepower

Returning to the car analogy, this is like creating a weighted average between a car's highway and city MPG.

All pool industry pros really need to remember is the higher the WEF, the more efficient the pump. This can help with pump selection. After all the usual criteria are considered, such as head and flow, plumbing diameter, physical size of the pump (so it will fit into the space you have at the pad), etc., WEF is a good way to give a customer the lowest utility bill possible.

All things being equal, a higher WEF means higher efficiency.

WEF will now be listed on the label of all pumps.

TOTAL HORSEPOWER (THP) AND HYDRAULIC HORSEPOWER (HHP)

The industry has always compared pumps using the term "rated horsepower," which was always a little bit misleading when you started comparing pumps between different manufacturers. And then you'd run into the terms "up-rated" or "full-rated" to be multiplied by the "service factor," and the result was a lot of label confusion.

Total Horsepower (THP) and Hydraulic Horsepower (HHP) will be the terms used to evaluate the power of pumps going forward.

The DOE regulation requires manufacturers to rate and label pumps using THP, which is the horsepower based on a fixed service factor of 1.0. THP measures power at the shaft instead of flow measured at the impeller.

Another measure of performance, HHP, will be determined under lab conditions by the manufacturer, typically displayed to two or three decimal places, for instance 1.587 HHP. It's based on the flow you can get at maximum RPM under a standardized set of conditions (20,000 gallon pool, 2-inch plumbing with an inline cartridge filter). So in that way, since it measures all pumps against the same standard conditions, HHP is a good way to compare different pumps.

RELATED: Coming Soon: DOE Pump Regulations

Again, it won't tell you what the pump will deliver at a particular pool, since that pool will be different from the standardized one above. But you will know that a 1.587 HHP pump will deliver more flow than a 1.062 HHP pump for the same pool.

THE REASON WHY

As we sort through all the terminology and strictures of DOE, it's important to keep in mind why this is happening. It's happening because for decades, pool pumps have wasted a staggering amount of money and energy*, and caused a large and unnecessary amount of pollution. Overall, the purposes of the pool pump can be achieved more efficiently with the use of variable-speed pumps.

* According to a study cited in the DOE regulatory document, replacing an average, standard-size pump today with one meeting the DOE e fficiency requirements will save $2,140 dollars over the lifetime of the pump.

This article first appeared in the July 2021 issue of AQUA Magazine — the top resource for retailers, builders and service pros in the pool and spa industry. Subscriptions to the print magazine are free to all industry professionals. Click here to subscribe.