Click to enlarge

Click to enlarge

But what about the other factors, such as the plumbing size and layout, and selection of valves, heaters, chlorinators and filters? How much do they affect energy efficiency?

Jeff Farlow, program manager of energy initiatives for Pentair, decided to conduct a case study aimed at answering those questions. "We wanted to demonstrate the additional savings and benefits you can obtain by combining variable-speed pumps with enhanced hydraulic efficiency," he says. "An efficient system starts with a variable-speed pump, but it's clear that those savings can be dramatically increased by addressing other points in the system."

The pool Farlow selected for the study contains 36,000 gallons and was plumbed exclusively with 1½-inch rigid PVC pipe. It was equipped with a sand filter and in-line chlorinator. The system had already been upgraded with a variable-speed pump and was experiencing significant energy savings. All of the improvements for the study took place on the equipment pad; none of the other plumbing in the pool was altered.

All of the existing equipment was removed by cutting both the suction and return pipe entering the equipment pad at ground level. The equipment pad was re-plumbed with two-inch rigid PVC pipe.

In terms of equipment, Farlow installed a new in-line chlorinator and a new cartridge filter, both chosen for their improved hydraulics due mostly to the reductions in fl ow restrictions. The existing variable-speed pump was re-installed so that any changes in system performance were directly due to the hydraulic modifications on the equipment pad.

The pump and system performance was monitored before and after the retrofit using a BK325 clamp-on kW meter, along with vacuum and pressure gauges to determine total system head in feet of water.

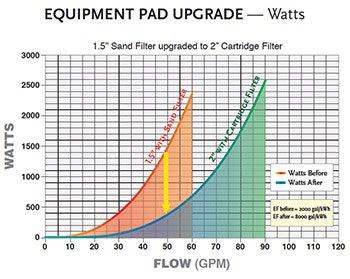

The results were dramatic: The pump's power was reduced 77 percent from 1,500 watts to 350 watts while maintaining a consistent 50 gpm flow rate both before and after the retrofit. The total system pressure was reduced 69 percent, from 65 feet of water to 20 feet. Before the retrofit, the pump was operating at 3,000 rpm. But by removing the hydraulic restrictions to fl ow, the pump was able to deliver the same 50 gpm at only 1,600 rpm.

Based on both improved hydraulic efficiency and lower pump speed, the pump's energy factor (gallons pumped per watt-hour consumed) increased from two to eight. That improvement translated into an increase from 2,000 gallons/kWh to 8,000 gallons/kWh. In terms of cost, the upgrades reduced the cost for one 12-hour turnover from $2.16 to $0.51, a 76 percent savings.

According to Farlow, one of the keys to the dramatic savings was to the removal of the 1½-inch multiport backwash valve. "That was No. 1 on the list," he says. "Whenever water has to make the turns in the backwash valve, you're dramatically restricting the fl ow. Second to that would be the filter itself. We found the cartridge filter is far less restrictive than the original sand filter."

Farlow places the less-restrictive chlorinator and upsized plumbing and improvements in the layout as third and fourth on the list of contributing factors. "Most people do focus on the variable-speed pumps, as they should because that's the first step in improving system efficiency," he says. "But based on these results it's obvious that with some very basic hydraulic improvements on the equipment pad, you can achieve even greater savings."

Note: the results of this case study are indicative of only this pool and no others.