The surge in popularity of fiberglass pools has been well-documented in recent years. In many cases fiberglass pools are being added to a builder's lineup to provide a more comprehensive product line, as the different types of pools offer complementary strengths and thus allow a builder to serve a wider spectrum of customers.

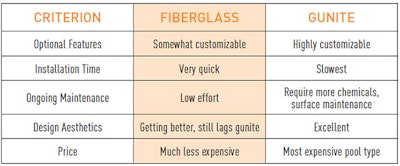

For instance, gunite is more customizable, but it also requires longer to build and more effort in ongoing maintenance. Fiberglass costs less and goes in quicker, but narrows design choices. These complementary strengths allow pool building companies to match features and price points that fit the individual customer.

But the type of pool installed also has a dramatic effect on the operations of the builder, who deals in the practical realities of labor, vendor supply lines, and scheduling to obtain the optimum result and the best bottom line at the end of the year. And according to builders who are adding fiberglass to their lines, this is where, like the material itself, fiberglass really shines.

Complementary strengths of different pool types help builders meet customer desires and priorities.

Complementary strengths of different pool types help builders meet customer desires and priorities.

LESS INSTALL TIME MEANS MORE INSTALLATIONS

Jason Branco, Aqua Med Pools, Dighton, Mass., got into the pool business in 2006 doing vinyl liners and gunite, building, service and repair. It wasn't until much later that he added fiberglass to the mix when he realized how it would help in scheduling.

"I have 3-5 person crews, and I'm on all the jobs," Branco says. "My fiberglass jobs take 1-3 days which makes it very easy for my crew to stay organized and efficient. We can do more fiberglass installations in a year than we can do vinyl liner installations, and in fact, this has freed us to do more service work as well."

The small, fast crews and the nature of the fiberglass pool also helps insure his plans against that one pervasive risk all northern builders face: a sudden cold snap.

RELATED: The Fiberglass Revolution

"The water tables in New England, freeze-thaw conditions, and temperatures — all affect how quickly you can get a vinyl liner installed," Branco says. "And these are not factors for fiberglass pools. You can install fiberglass pools when it's really cold — you don't need to worry about vermiculite bottom issues from high water tables. And from an installer's perspective, you don't need to have as many workers or crews to build the same amount of pools.

"Getting a vinyl liner pool finished can take us up to 2-4 weeks for site preparation, liner installation and dealing with timing and weather issues. This compares to a fiberglass pool that will take 1-2 weeks — including the deck and fencing — and gunite that can take up to 8 weeks. Vinyl-liner and gunite pools are subject to variables that aren't variables for fiberglass pools."

Bob Schaeffer, co-owner of Bob's Pools in Friedensburg, Pa., is looking at the same sort of labor allocations and some of the same weather issues. "We can install a fiberglass pool in pretty cold weather; something you cannot do with a vinyl liner. The only thing that can slow down a fiberglass installation is wet weather, which makes it hard to get the heavy equipment on the job, but this is pretty much the same for any pool.

"We only need a crew of three guys and we are done in 1-2 days. It's a no brainer when you have a short season."

RELATED: Fiberglass Pools Taking Market Share from Gunite

It's that short northern season that helps drive fiberglass pool sales above the frostline, where they are far more popular than they are in the gunite strongholds of Arizona, Texas and California. There's just less time to get pools in the ground each year, so speed becomes even more of an imperative. Gravel graded to the exact shape of the pool supports the shell.

Another factor in this northern fiberglass phenomenon is the relative scarcity of labor. While of course fiberglass also requires labor, it demands less of it and over a shorter period of time per pool than gunite. And with the pool shell already finished at the factory, there's no need for workers skilled in the art of finishing.

Aqua Med Pools' Cat 315 excavator carries the pool into the backyard. The same excavator that brings the pool digs the hole. (Photo courtesy Aqua Med Pools)

Aqua Med Pools' Cat 315 excavator carries the pool into the backyard. The same excavator that brings the pool digs the hole. (Photo courtesy Aqua Med Pools)

CRANE, TELEHANDLER OR EXCAVATOR

Concrete pools are poured in place, and vinyl pools assembled, but fiberglass pools are created through a completely different process. Fiberglass pools are built in a factory, stacked and shipped on flatbed trucks, and then lifted into place using hydraulic equipment. This unique process allows clever builders the opportunity to squeeze money out of the supply line in various ways.

One way of keeping costs down is working in concert with the competition for the benefit of all. Schaeffer cooperates with other fiberglass builders to cut everyone's per-unit shipping costs to the bone. "We have a truck to transport the pools so we can really control the timing. We deliver our own pools and help deliver fiberglass pools to other installers within a 100-mile radius of our shop. We also have our own water trucks allowing us to be completely in control of all aspects of timing for the pool installation. Water delivery is something we do for other builders in our area as well."

RELATED: The Future Of Fiberglass Pools

Branco agrees that minimizing freight cost is key. "Basically, you are paying by the mile; we pay roughly $3 to $5 per mile for shipping. These pools can travel through several states, so the shipping requires daily or weekly permits for traveling — similar to modular homes, the wide load hauls. Massachusetts requires a state police escort on anything that is 15 feet, 9 inches or wider, adding to the cost. Much like mobile homes, you need a special permit if you're getting product that is more than 16-feet wide.

"So if I'm getting pools from New Jersey the freight is just 400-500 miles, whereas other pools might be shipped to me from over 1,000 miles away. I may end up paying $8,000 to $10,000 in shipping costs. To lower the price, I try to order four pools at a time and sometimes they can stack into one another. This saves on the per unit shipping costs."

When the pools show up on the truck, some companies lift them into place by crane, but others strap them to the bucket of an excavator or the blades of a telehandler (basically a forklift with a telescoping boom), drive them to the hole and settle them down. Arranging the heavy equipment presents a puzzle to be solved: Do you rent or buy? Can you work out a deal with other pool companies to create efficiencies that add to everyone's bottom line?

Michael Berggren, owner of Berggren's Backyard Oasis Pool Construction in Wenatchee, Wash., eschews the crane for the large excavator or telehandler because of the cost. Their telehandler can lift up to 10,000 pounds, which is plenty strong enough to handle the shells the company is dropping in. "If we are ever limited by space, we might need to use a

crane," he says, "but so far we haven't been limited in our access to the site.

"We rent the telehandler for $800 a day, and we own our own excavator. We hope we don't have to rent a crane because a manned crane costs $800 per hour and they require you to rent it for a minimum of four hours. For us, adding that $3,200 to the installation would be significant."

Unlike Berggren and Schaeffer, Branco uses a crane in concert with an excavator to move pools from the truck into position, but schedules multiple drops in sequence to keep rental costs down. "When I do the multi-pool shipments, we use a crane to lift them off one another on the day of arrival. So we schedule it so the crane can actually move from yard to yard (site to site) and drop each pool at each location. Then we go back and use a Caterpillar 312 or 315 excavator to place the pool in the hole. The same excavator that digs the hole is used to move the pool.

"With multi-pool shipments we will prepare all the holes, then drop all the pools in the same day — as they are being delivered. It's very efficient."

The holes have been prepped with a bed of 3/8 chip rock, compacted and graded to the exact grade of the pool. Then they set the pool in and check if it's level. If it's not level, they quickly lift it up and re-grade, then lay it back down till it's perfect.

RELATED: Fiberglass Installation Problems and Solutions

"Then we cut the holes into the fiberglass shell," Branco says. "The main drain, skimmers and returns. The holes are cut into the fiberglass just as they are cut into the fiberglass shells in the boating industry — like the portholes in boats or the fiberglass doors on homes, using a hole saw. Then we run the plumbing lines while backfilling over them. The last step is pouring a concrete collar."

Finally, Branco adds, "We also put a main drain on the fiberglass pool, but we place it more like a sidewall drain — on the lower portion of the deep end on the side about 6 inches up from the bottom. This is particularly useful, so as an installer, you don't have to worry about water table issues."

Gravel graded to the exact shape of the pool supports the shell. (Photo courtesy Bob's Pools)

Gravel graded to the exact shape of the pool supports the shell. (Photo courtesy Bob's Pools)

PADS AND SKIMMERS

Equipment pads are not unique to fiberglass pools, but Berggren would like to say a few words about improving the state of equipment pads overall as a courtesy to the service industry. "I know this is going off topic, but as a service tech, I find that many builders are not thinking about the service tech when they install and plan out their equipment pads. I have a degree in hydrology, so I understand the importance of using the right piping diameter and plumbing lines correctly to keep from creating undue stress on pool equipment. It's really important that they are well thought out for efficiency and serviceability."

Another place to head off future problems, Berggren says, in fiberglass pools because most skimmers aren't made for fiberglass pools. They are designed to be installed on a 90-degree wall — which works fine in vinyl liner or concrete pools with flat walls. But fiberglass pool walls are formed in the mold at a 7-degree angle, so in order to install a regular skimmer in a fiberglass pool, installers add a ring and silicon or glue to get the skimmer flush up to the deck. That silicon eventually cracks and turns into a leak.

"Thursday Pools has fixed this potential leaking issue by creating what they call the Lucky 7 skimmer that is made at a 7-degree angle to fit flush and eliminate any need for silicon around the skimmer."

RAPID PRODUCT EVOLUTION

Fiberglass pools, along with other products such as digital controls, automatic pool cleaners and LED lights, have been one of the pleasant growth stories in the industry over the last few years. Market share numbers for fiberglass, especially in its midwestern heartland, are expected to continue their climb into the new decade as the limitations imposed by the prefabricated shell are largely being mitigated both by builders, who have learned how to make the most of the area surrounding the pool, and by manufacturers, who have been quick to adjust to new trends.

RELATED: Fast as Fiberglass

"What I find is that fiberglass pool manufacturers have included all the features that consumers want," Branco says. "They want tanning ledges, big stairs to sit on, safety ledges around the deep end to make the pool more user friendly for all ages. And none of these features require an additional charge — it's all a part of the price."

These photos depict, in order, stages in the development of a fiberglass pool built by Berggren's Backyard Oasis. The repeatability of the process allows fiberglass teams to develop the speed necessary to finish a beautiful pool such as this one relatively quickly. (All photos courtesty of Berggren's Backyard Oasis)

These photos depict, in order, stages in the development of a fiberglass pool built by Berggren's Backyard Oasis. The repeatability of the process allows fiberglass teams to develop the speed necessary to finish a beautiful pool such as this one relatively quickly. (All photos courtesty of Berggren's Backyard Oasis)

DON'T GO DEEPIt's hard to find a fiberglass pool with a deep end nowadays — you almost never see that in a new fiberglass shell, but that change reflects the change in consumer sentiment in the last few decades and the trend toward declining depth. "Pools are used more when pools are shallower," Branco says, "allowing people to use the entire pool to play games. Six feet has become the most common pool depth. The old 8- to 10-foot deep diving ends use a lot of water, and then there is a huge area of the pool that no one uses. And the really deep pool makes it difficult to maintain water chemistry, as it's hard to get good circulation of the water in the deep end. Also, deep ends with diving boards actually require more homeowners insurance, but installers can place a rock on the deep end edge and people can still jump off of it." |