For the last quarter century, builders and industry suppliers have been working to strengthen and beautify pool plaster by adding aggregates like rock, quartz and graded marble to the matrix that's applied to cement pools. Plain plaster, once the only choice for homeowners, has been losing share to these products, which manufacturers say are sturdier and stand up to homeowner neglect better than plain plaster.

While builders and homeowners in all parts of the country have discovered the numerous aesthetic and practical benefits of these products, there's a lingering notion among some in the industry that well-known products like Pebble Tec, Diamond Brite and others are best suited for higher-end pools. That's not the case, says Julie Dobbs, Western regional sales manager for Pebble Technology in Scottsdale, Ariz.

"We have a challenge as salespeople when builders tell us, 'Well, I only present Pebble Tec on my $80,000 pools,'" she says. "That shouldn't be the mentality, because no matter how much money people are spending on their pools, they really want to protect the investment of their finishes." Dobbs cites a scenario of a customer with a moderately priced pool - or any pool for that matter - who doesn't pay proper attention to water balance and chemistry. That customer may save money up front, but if the pool needs a replaster several years down the road, it can end up costing as much or more than a pebble, quartz or comparable finish would have.

"I encourage people to at least let the homeowner make the decision," she adds. "They have to decide what they want to do to protect their pool."

The Basics

Technically, all pool plaster contains aggregates. Plain white plaster, for example, is made by adding crushed marble, commonly known as pool sand or marcite, to Portland cement. Although this aggregate has served pool builders and homeowners pretty well, it doesn't necessarily stand up to harsh chemical environments like the newer ones do. But how do these alternative aggregates work? It's pretty simple, really."

In your newer, modern-day finishes, to achieve a particular look, they'll come in and remove the 'cream' off the top of the surface after it's been troweled," says Michael Bell, national sales manager for SGM, Pompano Beach, Fla. "This gives you the exposed aggregate."

The exposed aggregate in effect hides the cement, which, according to Randy Dukes, who handles technical sales for Aquavations Corp. in South Miami, is by far the weakest part of the surface matrix.

"It really started with Pebble Tec back in the early '80s," he explains. "They started taking the top layer of cream off and exposing the aggregates that were underneath. In their case, it was rock."

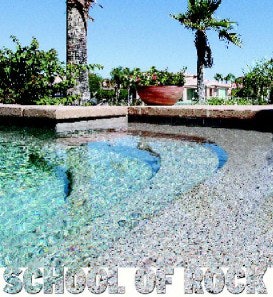

This rock, once exposed, offers homeowners a couple of appealing benefits.

"People buy Pebble Tec for two reasons," Dobbs explains. "One is the aesthetic value and the other is the longevity and durability. We call it virtually bulletproof."

Another benefit to Pebble Tec and similar stone surfaces is that any blemishes that might occur are more difficult to see, says Dobbs.

"With just a plain colored finish, you're able to see stains or dirt on the bottom much more easily," she says. "People like the fact that when it's a little dirty, it's OK."

Despite these benefits, manufacturers admit, pebble surfaces aren't for everyone. All agreed that the No. 1 customer objection to pebble-type aggregate finishes is that they're, well, full of little rocks. "It can be hard on your feet," Dukes says. "And it can be a problem for some if you've got a play pool or women sitting on benches with - I used to say $100 bathing suits, I should start saying $200 and $300 suits now. If the plasterer isn't on his game that day and he's got a rough bench, that can be an issue."

Pebble Technology's Dobbs agrees, but says some of these objections to the texture can be skirted by skillful salespeople.

"That is our biggest objection," she says. "But I've heard hundreds of pool builders say, 'Well, my customers complain about it being rough before they even buy it, but once they have it in their pools they realize it's really not.' But it's a natural reaction for someone to say, 'I'd have rocks in the bottom of my pool?' Pool builders can talk about the success they've had with it and use their customers for referrals."

Smaller pebbles are another way to appease customers who object to the feel of stone aggregate. They tend to make a smoother surface, but look a little less natural than finishes with larger stones, Dobbs says. For that reason, they're often specified in more formal pools than large-aggregate finishes, which afford a more natural look and are frequenly used in free-form pools.

National Pool Tile, a division of Pentair Water Pool and Spa, makes an array of aggregates, marketing its pebble-type finishes under the StoneScapes name. "The mini-stone is more popular because it does tend to be a little smoother," says Don McChesney, national sales manager.

Still, he concedes, not everyone cares for pebble aggregates. "Pebble can be a little rough," he says. "It's definitely nowhere near as smooth as plaster."

The Next Generation

In an effort to match the superior durability of exposed-stone finishes with a product that was a little easier on swimmers' skin and looked more like a traditional pool finish, many in the industry turned to quartz in the 1980s, says Dukes. Quartz sold fairly well initially, but it really caught on with customers, he explains, when 3M came out with blue- and teal-colored quartz, which it sold to companies such as SGM, Florida Stucco and other so-called "preblenders," a term that separates firms that sell bagged aggregate for mixing with cement from builders who mix the aggregates according to their own recipes on job sites.

Quartz aggregates tend to cost less than stone and give customers a wide array of color options, many of them lighter than stone finishes, another appealing characteristic.

"You're finding penetration on the more moderately priced pools with the Diamond Brite product," Bell says of SGM's quartz aggregate, which comes in a range of colors and price points. "If you come to Florida, you'll be hard pressed to find a swimming pool that does not have a Diamond Brite-type finish. Pebble is starting to take off, but you find virtually no plaster pools. Literally, there are hardly any. So even on your budget, cookie- cutter pools, people put the quartz products in there."

National Pool Tile calls its quartz aggregate finish QuartzScapes, and Mc- Chesney points out that quartz is similar to the silica sand ordinary pool plaster contained years ago, until that sand became scarce and was replaced by softer marble dust. He's a big fan of quartz's toughness and its versatility. "[With quartz] we give customers a very durable and long-lasting surface, and we've also incorporated coloration," he says. "For example, in a QuartzScapes pool there'd be 70 percent uncolored quartz and then 30 percent might be blue or teal. Now, beyond that you can add a pigment pack and create a blue color for the whole pool." Another new aggregate that National Pool Tile offers is called Beadcrete, which McChesney explains is an aggregate made with irregularly shaped colored-glass beads and costs more than the others but less than an allglass- tile pool.

The beauty, versatility and toughness these exposed aggregates deliver do come with a higher price tag; though, as Dobbs points out above, the overall costs of ownership is similar if a homeowner finds him or herself needing to replaster just a few years down the road.

"One of the issues with higher-end finishes is builders don't understand the real pros and cons," Bell says. "For example, I was talking with someone recently. He was building $65,000 to $75,000 swimming pools and putting in white plaster.

"Someone like that is really selling their customers short by not offering a better finish. You don't go out and buy a new Lexus and have the manufacturer put on tires that are only going to last you 10,000 miles. Sure, it's going to cost a little more to get tires that'll last you 50,000 miles, but I think most people would be willing to pay just a little bit more."