A partial pool closing (PPC), also known as a soft pool closing, is a practice of putting a pool in a state of limited use and operation that does not involve removal of the pool's primary equipment or the draining of water. To contrast, a Complete Pool Closing (CPC), also known as a hard closing or winterization, would include installing a cover over the pool's surface and, in some circumstances, removing a pool's equipment.

RELATED: Closing Time: 2020 Winterizing Product Focus

Local climate conditions and customs usually dictate the type and timing of closing. Additionally, a PPC may be performed if the pool is going to be unused for an extended time period. There are some benefits to a PPC — for example, reduced energy and chemical costs as well as time spent performing maintenance, when compared to a fully operational pool.

PARTIAL CLOSING BENEFITS

- Helps maintain water quality and lessens the likelihood of precipitation of metals or salt scale during the pool's off-season

- Reduces chemical and energy consumption

- Reduces water use by not draining in a CPC

- Keeps the pool and lines from freezing by running the pump at reduced capacity

- Makes it easier to re-open the pool

- Protects the equipment and interior finish from damages caused by freezing temperatures

PRECAUTIONS

- Maintain water balance throughout the entire period of the partial pool closing

- Maintain primary sanitizer residual

- Remove and/or winterize all secondary and supplemental systems

- Remove or winterize salt chlorine generators

- Maintain water levels in pools for proper pump and filter operations

- In freezing temperatures, day or night, pumps should run 24/7 until the danger of freezing is removed

STEPS FOR PPC:

- Pool needs to be brushed and vacuumed to remove any organic debris such as leaves to prevent staining.

- The pool filter needs to be maintained and cleaned to remove debris.

- Heater use is optional. It can be utilized to prevent freezing for short periods; however, continuous water circulation will typically prevent any damage caused by short periods of below-freezing temperatures.

- Booster pumps for cleaners, spas and water features will need to be removed and stored properly. In general, any equipment not being used regularly needs to be removed, as standing water may freeze and damage the equipment.

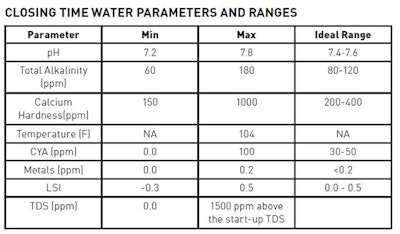

- Water needs to be balanced according to the published ANSI/APSP/ICC-11 standard but needs to be adjusted for cold water temperature according to the Langelier Saturation Index (LSI) formula. The LSI should be maintained between -0.3 to 0.5.

- Metal control agents should be added at pool closing and possibly during the off season. Regular chemical maintenance should be performed based on water testing results. Clarifiers and enzymes are optional and can be used as needed.

- A steady amount of primary sanitizer should continue to be added to the pool to maintain levels indicated in ANSI/APSP-11. Make sure to follow the label instructions.

- Although not necessary, pool covers can keep debris out and make it easier to maintain the pool. If a cover is used (either mesh or hard cover), the pool owner or operator needs to ensure the water level in the pool is maintained for the pump and filter to operate effectively. Additionally, the condition of the cover should be checked periodically for any damage and be maintained according to the manufacturer's instructions. Damaged covers should be replaced or repaired to their original condition.

WARNING: All solid safety covers must meet ASTM F1346-91 Standard Performance Specification for Safety Covers and Labeling Requirements for All Covers for Swimming Pools, Spas and Hot Tubs and have an automatic means of preventing water accumulation on top of the cover whenever the pool is covered. For example, this may be accomplished with a drain panel or a pump. Rainwater on the cover is a drowning hazard for children. Consumers must be made aware of the necessity of preventing water accumulation on top of the cover. - The pool pump needs to run at least 2-3 hours a day, or longer if necessary. If freezing temperatures are expected, the pool pump should run continuously until the danger of water freezing within the lines or at the pool surface is removed. Some pools are equipped with a freeze protection timer. These timers are designed to turn the pump on when the outdoor temperatures drop below the temperature set by the useradjustable thermostat.

- The pool water should be tested periodically and adjusted depending on the ambient air and water temperature. Colder climates need less testing. Normally testing is done once or twice a month.

- Follow the manufacturer's recommendations for secondary and supplemental systems such as ozonators or UV light to determine operation or removal of equipment.

- Salt Chlorine Generators (SCG) need to be removed and winterized following the manufacturer's recommendations. This is generally done by removing the cells from the SCG unit. SCGs are ineffective in producing chlorine in cold water below 50-52 degrees Fahrenheit. Some SCG units have settings for "neutral" or "winterize."

PPC - WHAT IT IS, DOES, AND DOES NOT

What It Is

PPC, also known as soft pool closing, is a practice of closing a swimming pool without removing the pool's primary equipment or draining water, and may be required for some pools in colder climates to avoid damage caused by freezing. The pool will operate very close to normal but may be covered and not open for use. There are different practices depending on geographical locations.

What It Does

A PPC keeps the pool in a state in which it will be simple to get the pool operational with minimal effort. It minimizes energy use due to the shorter pump operation, and colder temperatures may also reduce chemical consumption. Additionally, it protects the equipment and interior finish from damage caused by freezing by maintaining circulation.

What It Does Not

PPCs still require active maintenance by the pool operator. Pool equipment must be monitored to ensure that it is operational and proper water chemistry is maintained. Skimmer baskets need to be cleaned of any debris, and the pool needs to be kept clean if a cover is not installed.