For the past several years, aquatic designer and pioneer, Skip Phillips, has grappled with the challenge of making suction and return fittings disappear. Now, in this confusing season of the massive drain recall and the CPSC's rule reversal, Phillips has developed a new way to approach these fixtures, one that solves aesthetic problems and eliminates any risk of suction entrapment.

There's no escaping the fact that drains and other suction and return fixtures do not look good. In almost every pool and spa ever built, we force our clients to look at constellations of circular fixtures or square grates that can't help but draw attention.

Some would say the appearance of suction and return fittings is so common and expected that we don't even notice. I counter that it's never made any sense that we have no options other than fixtures that stand out against the pool finish. Sure, we've seen improvements in the form of colors other than white and drain covers that utilize matching finishes. And while I do commend drain manufacturers for trying, truth be told we all know those suction and return fittings remain visible to varying degrees.

Another partial solution is to eliminate drains altogether, an option that certainly solves the aesthetic problem where drains are concerned, and more importantly it's an idea heralded by some as the ultimate way to eliminate suction entrapment tragedies. That all sounds pretty good and again, while I do admire the bold thinking behind the "no-drain solution" there are far too many scenarios where drains are indispensable; most spas and all perimeter overflow systems are primary examples.

All of this is why for years I've scratched my head and even laid awake at night trying to figure out how to make drains convincingly disappear and at the same time obliterate entrapment risks.

Answers On Deck

Before I go any further, let me say unequivocally, I firmly hold that any rethinking of drains or suction points must put safety first.

My thought on that front is that as an industry we have to develop a solution that far surpasses the morass of issues stemming from the Virginia Graeme Baker Pool and Spa Safety Act. Ultimately, we need to go beyond that problem and use what we already know about unblockable drains, split drains, line velocities, as well as plumbing and pump size to develop new drain configurations that rely on the principles of physics and mechanical engineering to eliminate the risks.

To my mind, the time has come to render the entire issue obsolete, once and for all, and we be smart enough to make that happen. The issue has become far too complicated and instead of constantly chasing our tails trying to comply with the phalanx of requirements and recommendations contained in VGB, we need an elegant solution that completely eliminates the problem.

In The Slot

Years ago, I began experimenting with various drain designs and eventually came upon the idea of creating a new type of drain that utilizes an extremely narrow slot, the idea being it would be very close to invisible, or at least far more so than anything on the market now.

In developing this new type of design, I knew right away that a narrow slot would be extremely limited in terms of flow rate. Thinking it through I decided to take that limitation and turn it into an advantage by making the fixtures extremely large so that the flow would be distributed over several linear feet of slot.

This is when it dawned on me that this type of drain could solve the entrapment problem because the size of the drains would have to necessarily far exceed the specs for a so-called "unblockable drain" as it's defined in the Virginia Graeme Baker legislation, which calls for either split drains or drains that are greater than 18 by 23 inches. My plan was to use drains that are almost double that size and install them in a split-drain, cross-plumbed configuration, thus meeting the standard both as an unblockable drain and by way of always using split drains.

Assuming that the line velocity on the suction plumbing is four and a half feet per second, the velocity through any given linear inch of the slot is so low that you can't even feel any suction at all when you put your hand over it. In effect, these drains would be not only unblockable, but also deliver imperceptibly low velocities.

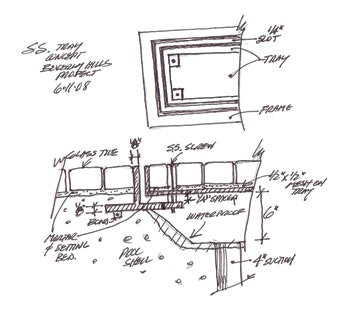

With all of that in mind, I began experimenting with different mechanical configurations. It didn't take long before I lit on the idea of having a simple frame that contains a solid tray, which would contain whatever finish material is being on the pool or spa. And I would use durable material; 5/16ths stainless steel that is powder coated to match the finish.

Barely Visible

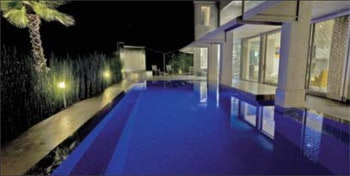

Once I had the design in hand, I needed to find a project where the homeowner was willing to let me try out my new drains. That opportunity appeared last year as part of a spectacular project in Beverly Hills, Calif. The project included was a three-sided vanishing-edge pool and a detached spa, both were to be finished with shimmering blue glass tile from Lightstreams Glass Tile of Santa Clara, Calif.

I particularly like the idea of using this approach in all tile pools because the slots can be made to line up with the grout lines, concealing them even further. In this case, I would use the fixtures for both the primary suction and vanishing edge return in the pool, and as the drains in the spa.

In terms of installation, these fixtures aren't much different than any other fitting, with the one exception being they do require large sumps due to their size. To make things easy, we decided to simply use foam blocks as spacers during the shotcrete installation, and then remove them afterwards.

Once the tile was installed and the pool and spa filled with water, the fixtures do very nearly disappear. And, as I predicted based on my hydraulic calculations, you cannot detect any suction at all because the velocities are so low, which has the added benefit of completely eliminating any chance of hair entanglement.

At this writing, I'm continuing to fine-tune the design. One concern, for example, is the width of the slot. The prototypes have a slot that's a half-inch wide, which is outside the specs required to prevent finger entrapment. Our new fixtures will have a narrower slot width, and likely be made even larger, again to accommodate the required flow rate.

My good friend and colleague Dave Peterson of Watershape Consulting (La Jolla, Calif.) is also working on his own version of the design, which will address the finger entrapment issue with some added wrinkles he's currently developing.

Finally, to be perfectly clear, these fixtures have not been independently tested and are therefore not yet certified on any level. My belief is that because they so far exceed standards maintained by ASME and ANSI that rating them will be a mere technicality.

My hope is that eventually these fixtures, which don't even have a name yet, will revolutionize the way we treat suction and return fittings, both in terms of safety and aesthetics. For now, I'm going to continue to refine the design and recommend the fixtures in all of my design work from now on.

With continued effort in this vein, I believe there will come a day when the letters VGB fade from memory and the sight of drain covers and grates are a thing of the past.

Comments or thoughts on this article? Please e-mail [email protected].