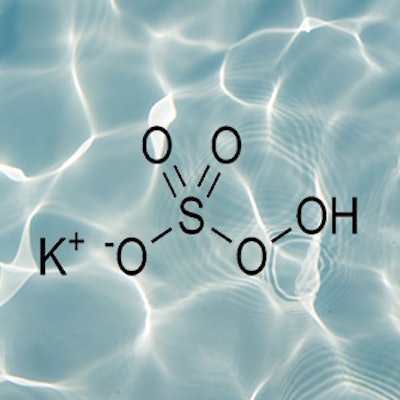

Potassium Monopersulfate (monopersulfate, KMPS or MPS) is a white, granular, free-flowing peroxygen that provides powerful non-chlorine oxidation for a wide variety of uses. It is the active ingredient in most nonchlorine oxidizers used for pool and spa/hot tub oxidation.

Most non-chlorine oxidizers contain 45% of the active ingredient potassium monopersulfate, but blended compositions are also commercially available that may contain buffers, clarifiers and/or additives for control of algae.

Potassium monopersulfate is not a sanitizer or algaecide and must be used in conjunction with an EPA-registered sanitizer. The role of monopersulfate is to provide effective non-chlorine oxidation — in other words, to react with organic contaminants and maintain or restore water clarity.

RELATED: Test Killers: Common Water Testing Interferences and How to Avoid Them

Non-chlorine oxidizers, like similar chlorine products, are intended to be used for supplemental treatment. They provide supplemental oxidation of contaminants to reduce the demand on the primary sanitizer. Monopersulfate is an alternative to chlorine oxidizers for applications when raising the chlorine residual (from chlorination) is not desired. Since the oxidation chemistry from monopersulfate is performed by “active oxygen,” it reacts with contaminants without using additional chlorine.

APPLICATION

Always follow label directions when using potassium monopersulfate products to treat swimming pool and spa/hot tub water. Potassium monopersulfate is compatible with all sanitizer products and systems. When used with biguanide systems, follow the biguanide manufacturers’ specific recommendations for the use of potassium monopersulfate.

It is recommended for use in indoor and outdoor residential and commercial venues. While there is no specific test to determine when and how much monopersulfate should be applied, there are guidelines that can be followed to ensure proper use. The primary parameters to be tested are free and combined chlorine. Free chlorine should always be tested, and adjusted if necessary, to ensure proper sanitizer levels. Testing combined chlorine indicates the level of contaminants bound to chlorine and the need for supplemental oxidation.

Pool and hot tub water should be properly balanced. This requires testing of the pool water balance parameters of pH, carbonate alkalinity, calcium hardness, and stabilizer (i.e., cyanuric acid). In addition to testing the standard parameters, an overall assessment of pool and hot tub water and air quality should be performed. Poor water quality and/or apparent chloramine odor, are key indicators that oxidation is required.

Regular oxidation with potassium monopersulfate will help manage combined chlorine levels and problems associated with chloramines.

RELATED: Understanding Ammonia and Nitrates

In the N,N-diethyl-pphenylenediamine (DPD) and ferric ammonium sulfate (FAS)-DPD test methods, any residual potassium monopersulfate will test as combined chlorine. This occurs because MPS reacts with potassium iodide in the DPD#3 reagent, thereby converting iodide to iodine, which reacts with excess DPD to produce a red coloration. To alleviate this issue, the following actions are recommended:

- Always test before adding monopersulfate

- Add monopersulfate in the evening and test the following morning

- Use a test kit that includes a reagent to neutralize residual monopersulfate in the DPD test series or...

- Use a test kit or strip that does not have this interference

PRECAUTIONS

In order to safely use and handle potassium monopersulfate products, all individuals involved in their manufacture, distribution, sale or use should be trained and knowledgeable about their properties. Safety information is available on the product label, safety data sheet and the manufacturer’s product literature. This safety information will include product and packaging disposal instructions and spill response information.

Potassium monopersulfate is a dry solid with strong oxidizing properties. It is very stable when stored in a cool, dry, ventilated area and not contaminated by other chemicals such as alkalis or easily oxidizable materials. Monopersulfate should not be mixed with other pool chemicals. Partially empty packages must not be combined, as this could result in dangerous mixing with incompatible materials having a similar appearance.

CAUTION: If mishandled, improperly stored, or contaminated, monopersulfate products can become unstable and dangerous, as is the case in general with oxidizing agents. Fire and/or evolution of toxic gases could result, depending on the nature and amount of the contaminant. As with any oxidizer, monopersulfate can oxidize metals and may result in staining of pool and hot tub surfaces. When used with mineral systems, check manufacturers’ directions for use.