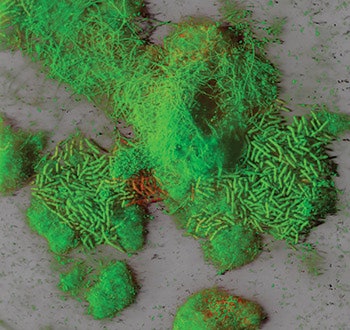

This image shows the diversity of bacteria found in a biofilm that grew in drinking water. Photos by Lindsey Lorenz, microscopist for the Center for Bioflim Engineering, Montana State University.

This image shows the diversity of bacteria found in a biofilm that grew in drinking water. Photos by Lindsey Lorenz, microscopist for the Center for Bioflim Engineering, Montana State University.

Last month, we published a discussion about the murky subject of biofilm. I researched and wrote the story to fill in what seem to be wide gaps in our industry's shared knowledge about this ever-resent form of bacterial colonization, a blight that exists not only in pools and spas but in virtually all other types of plumbing systems that transmit water.

The physical reality of biofilm is not just slippery and slimy, it is also potentially dangerous and should be a point of awareness for aquatics professionals. At the same time, it's a genuinely fascinating topic that we presented with a couple unusually grotesque images.

Here we see the relationship between biofilm and hard water deposits (the white crystals). This demonstrates how a biofilm matrix may contain inorganic substances as well.

Here we see the relationship between biofilm and hard water deposits (the white crystals). This demonstrates how a biofilm matrix may contain inorganic substances as well.

Unsurprisingly, we received a number of comments, questions and some critiques of our coverage. Among that wave of feedback was the following missive from builder Rob Lane of Preservation Pools and Fountains, Ltd., in Merriam, Kan. In his response to the article, Lane raises a fascinating question about recommended flow rates in pool and spa plumbing and how the slowing of those rates in the name of hydraulic efficiency could contribute to the formation of biofilm. He writes:

RELATED: The Secret Life of Biofilm

"I first started studying biofilm in relationship to city potable water delivery. My goal was to bring pool ideas to the cities for big contracts. The water sits in their pipes and/or moves very slowly most of the time. The pipes are generally sized for maximum usage and fire fighting. Cities can't superchlorinate their systems so their current answer is to open up the fireplugs every so often. When that no longer overcomes the biofilm, they replace the pipe.

Any pool guy that has used a fire hose to fill a pool has seen the junk water that comes out of it at the start. When I fill a pool, I blow the line clean for 15 minutes out in a field. For many years, my father and I built pools in which we generally sized the suction pipes at 6-feet per-second and the return pipes at 8- to 9-feet per second. In the early years, most of our competitors were undersizing the plumbing — but you can't suck the ocean through a straw.

With the energy crunch and introduction of variable speed pumps, I am now seeing piping systems that are very oversized. Typically, it is a 2-inch pipe or larger run out to each skimmer and return, for example.

This idea is sold as a good thing because it conserves energy and saves money. The pump will rarely be run at a speed to run at 6 fps on suction or 9 fps on the return side. If the public utility experience is a guide, then this situation should lead to the generation of a lot of biofilm and health problems for our customers. The funny part is that we are causing this problem ourselves by over piping and under running."

In essence, Lane's concern boils down to the issue of "scouring" plumbing by the pressure and speed of water flowing through it. Do higher flow rates, in fact, inhibit the formation of biofilm and if so, to what extent and at what speeds? A broader question stems from Lane's observation: To what extent should we as an industry be purging and cleaning pipes?

Our industry has never paid much attention to biofilm. Information on the subject, let alone recommendations, are hard to come by (outside of a handful of trade articles in AQUA and various manufacturer recommendations). As a result, this is an area where we may do well to look outside our immediate industry to see how other categories of professionals approach the challenge.

For example, take a look at what the American Water Works Association had to say on the topic in a report it published titled "Investigation of Pipe Cleaning Methods." Although the document is over 15 years old and does not focus on pools and spas per se in favor of public utility applications, the exploration of pipe-cleaning methods may hold some important signposts for recreational water systems.

RELATED: Attack The Spa's Biofilm Sanctuaries

"A well-planned, well-executed pipe-cleaning program provides many benefits. Cleaning removes sediment and biofilm from pipes, thereby reducing the risk of water discoloration, taste and odor problems, coliform regrowth, and regulatory noncompliance. Pipe cleaning can also remove scale and tuberculation, dramatically improving hydraulic capacity, while reducing pumping costs. Yet despite these benefits, many utilities clean pipes only occasionally — usually in response to customer complaints, or to address specific water quality problems. Uncertainties about how, when, and where to clean pipes have contributed to this oversight."

The report goes on to examine common techniques including conventional flushing, unidirectional flushing, air scouring, swabbing, pigging/drag scraping and rack-feed boring. Less common techniques it examines include chemical cleaning, jetting, and ball cleaning.

One of the critiques of our biofilm piece was that it did not go far enough to define the importance of flushing plumbing systems as a way to control biofilm. That may be a valid point, but it also indicates the need for a thorough investigation by our industry into what dealing with biofilm actually entails, and perhaps even to the point of considering whether or not our recommended flow rates are contributing to its formation, as Lane suggests above.

In short, how do we get the gunk out?