Creating pools, spas and other aquatic features that maximize energy efficiency first requires understanding a number of basic truths about the way these systems utilize electricity and energy for heating, explains Dave Peterson, owner of Watershape Consulting (Solana Beach, Calif.) and chairman of the education council for Genesis 3. To make things simple, Peterson offers the following point-by-point breakdown of basic engineering measures and principles that when properly applied, help make the most of homeowners’ or commercial clients’ energy resources.

At the risk of stating the obvious, we all should know that if you design and build things well, it’s going to reduce maintenance and contribute to the most efficient use of resources.

We also know the opposite is true. If, for one common example, you undersize plumbing to save a few bucks, there’s a good chance the skimmer won’t work properly, meaning there will be more debris in the water, which will compromise water quality and result in added labor and expense to maintain the pool. In so many ways, large and small, basic measures such as plumbing size can result in either tremendous loss or offer great savings over time.

It’s really just common sense. When we talk about going “green” in pool and spa design and construction, we’re mostly talking about measures that should be used on each and every project. Playing it smart with energy, chemicals and water use means keeping a number of important concepts in mind all at the same time. Fortunately, it’s not difficult if you break it down to specific steps, which is why I’ve generated a punch list that will help focus your efforts as you work to create systems that work properly and avoid waste.

A number of these items are optional and may or may not appeal to the client. To start off, however, we’ll look at measures that should be used on every system that moves water.

POWER IN MOTION

Flow rate (gallons per minute): Knowing your required flow rate is the first step in creating an efficient system; forget the pump or the plumbing size for a moment and simply calculate the flow requirements for all of the components and features in the system.

On the simplest level, you should only move what you need to move. As an example, let’s look at filtration, the most fundamental element in any system. If your filtration system needs 50 gpm, don’t pump 60 — because you’ll be using energy to generate a flow rate that’s unnecessary.

Of course, turnover is the key calculation when it comes to filtration and flow rate. Commercial pools are required to have a six-hour turnover rate, largely as a means to ensure water quality even in times of high bather load. In my practice I use the same criteria for residential pools. You can always decide to run the pump longer if need be, in which case I slow things down and realize major energy savings because the system is sized for a six-hour turnover. Keep in mind that when you cut the pump speed in half, according to the affinity law you realize an 87 percent reduction in energy.

Pressure (feet of head): Pressure is related to flow rate because the faster water passes through the pipes, the greater the pressure loss. To control the pressure loss you have to size the pipes appropriately to keep the velocity down. You don’t need to oversize them, even though some people see oversizing as a way to build in an efficiency buffer.

In my work, I design for 4½ feet per second maximum on the suction side, which exceeds industry standards. In doing so I’ve found that you’ll wind up with pipes ranging from two and a half inches up to four inches for most residential projects. That might seem like a lot to residential builders working with two inch or lower, but you’ll find that when you keep velocity down using the larger sizes the efficiencies are significantly improved and so is overall system performance and component service life in many cases.

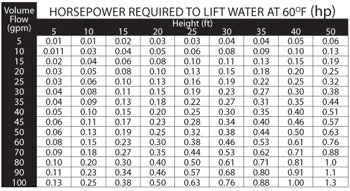

Flowrate x pressure = power: More specifically, gallons per minute x total dynamic head (feet of head loss)/3960 = water horsepower. This simple calculation shows that when you reduce flow rate and/or head you reduce water horsepower. Again, the larger the pipe, the lower the pressure loss, the less energy required.

Water horsepower refers to the energy going into moving the water, which is different than the power going into the motor or the power going from the motor into the pump — the reason being that motors and pumps are not 100 percent efficient.

In general, swimming pool pumps are around 70-percent efficient. That means if you calculate that you need 1 water horsepower, you need to divide that by 0.70 to size the pump, which gives you about 1.4 mechanical horsepower. Then if the motor is 90 percent efficient, then you divide 1.4 by 0.90 to determine the motor or electrical horsepower. You wind up with a 1½ horsepower pump/motor.

Use efficient pumps and motors: Here’s where it’s helpful to be able to read pump curves. You can compare 1½ horsepower pumps by different manufacturers and see that one or the other will move more water at a higher pressure with equivalent horsepower. The higher the efficiency, the less power is lost in the pump/motor combination.

Motor efficiency is a complex issue and probably the subject of an entirely separate article. Keeping it simple for this list, manufacturers offer efficient versions of motors, the difference in many cases being a rating of 88 percent versus 92 percent. That might not sound like a lot, but over time that four percent difference will result in significant savings. And don’t even get me started on the whole motor service factor game!

Power phase and voltage: Also, keep in mind that as a rule, three-phase power is more efficient than single phase and 240-volt single phase is more efficient than 120 volt. When you have a choice between wiring to 240-volt or 120-volt at the service panel, it’s always better to wire to the 240-volt because of the reduced amperage.

The same thing is true when choosing three-phase instead of single phase because you’re using power that’s more similar to the delivery system over the power line. Changing from three-phase to single-phase requires a transformer, which will have its own level of inefficiency.

Variable-speed drive pumps: Another vast topic unto itself, these pump systems are transforming expectations for performance, and when used in a well-designed system can deliver tremendous savings compared to traditional single- or multi-speed pumps.

One of the ways that VSPs save power is by eliminating the need to use valves to throttle down flow to a given feature. For example, if you’re using a single-speed pump and you want to reduce the flow, say, to cut down on noise or turbulence from a waterfall, you’d have to make that adjustment with a valve. In that situation, you’re not reducing the power, just the flow rate, and that’s wasteful. With an VSP, you can adjust the flow rate at the pump, which translates directly to energy savings.

It’s important to keep in mind that just because you’re moving the water more slowly with an VSP, you shouldn’t then go ahead and downsize the plumbing. That essentially defeats the purpose of the variable-speed concept and will drastically reduce savings.

MULTIPLE MEASURES

With those basics in place, you can take efficiency to another level through a number of specific features and concepts that are tangential to basic hydraulics and power use.

Heat loss and covers: Some heat is lost through radiation to the sky or thermal conduction through the walls but most heat is lost through evaporation where the hottest (heat rises) molecules leave the surface of the water. Automatic safety covers prevent both evaporation and heat loss and in effect extend the swimming season because it’s more affordable to heat water when you keep it covered most of the time. As a general rule: an automatic cover will cut down evaporation by about 75 percent. Covering up also helps keep the water cleaner, which reduces maintenance and chemical use.

Floating bubble covers are good but generally not used consistently and they don’t seal as well as automatic covers. Trees and buildings may be good windbreaks that help reduce wind-driven evaporation but they may also shade areas that would benefit from solar heat gain.

Vanishing edges: These popular features also play a role in heat loss. Increased surface area and moving water both contribute to higher evaporation. The solution is to reduce this effect by not sheeting huge flow rates over the edge — I typically design with a very low wet wall effect and no sheeting.

Passive solar: There’s no arguing with the notion that using the sun can be a fantastically efficient way to heat water, essentially because the source of power is free. You do use energy to pump water to the solar panels, but when you consider that they’re rated for very low flow rates — five gpm for the panels I use — and once the water exits the manifold in the panels gravity takes over and helps move the water to the pool, it doesn’t take much to move the water through the system.

Solar panels do need to be properly sized. Most manufacturers specify that you want the panels to measure at least 80 percent of the surface area of the pool. And the panels must be able to be located with good exposure.

Photovoltaics: Using the sun to generate electrical power is nothing new across a range of applications outside our industry, but it does remain a somewhat unusual idea for operating pool and spa systems.

I’ve learned, however, from direct experience that these systems can and do work. Not long ago I engineered a project on the Caribbean island of Antigua. The property had no power service and had to be run entirely on a photovoltaic system, including a pool with a vanishing edge. Another client of mine installed photovoltaic roof tiles and during the day, even with the pool and edge running, his electrical meter was spinning backwards. Of course, at night it went forward, but at the end of the month, he zeroed out his electrical bill.

My hunch is that with advancements in the technology, especially where photovoltaic roofing products go, we’ll see more and more homeowners becoming interested in the concept.

Smart meters: A smart meter doesn’t save power in and of itself, but it does give a power company the ability to determine when you’re using most of your power. Some power companies will look at the usage times and offer to cut the rate for power you use off hours, meaning nighttime. This has the effect of flattening the demand on the power generators while providing savings for users who do things like run their pool at night.

That said, if you’re using passive solar heating, it’s still better to run the solar pump during the day even if it’s at the higher power rate because the largest energy loss in any pool is usually heat loss through evaporation.

Lower temperatures: Keep in mind that the higher the temperature, the greater the evaporation, meaning lower temperatures reduce evaporation. Homeowners are likely to find a significant difference maintaining a pool at 82 degrees instead of 84, even though most people would barely be able to feel the difference themselves. When combined with a pool cover, lower temperatures can dramatically reduce heating costs.

LED lighting: It’s no secret LED lighting fixtures are finding their way into a number of common applications replacing incandescent light. One of the big reasons is the measurable energy savings. A 75-watt LED fixture will put out around the same light as a 500-watt halogen fixture — a huge difference. In aquatic applications, LEDs make great sense: the fixtures are smaller, some don’t require niches or bonding wires and we’re finding that the fixtures last longer.

Ozone generation: Ozone is the most effective oxidizer and sanitizer used to treat water. You can use far less chlorine and acid, which means you’re not purchasing nearly as much chemical, which in turn means less is manufactured, stored and transported. Plus, ozone units don’t draw a tremendous amount of electrical power.

When you think about that relative to the cost and environmental impact of having a service company drive around drums of chlorine, ozone just makes sense. Also, because you’re using less chlorine and cyanuric acid, you’re not contributing nearly so much to TDS, which in turn means you’ll have to drain and replace water less often, which conserves a precious resource.

High-efficiency heaters, heat pumps and exchangers: Heater design has come a long way over the years, to the point now where we have units that are rated at 97 percent efficiency.

There are a number of heat pump types and a variety of schemes where heat energy can be transferred from the air, ground or even well water to swimming pool water. The same can be said for heat exchangers that are sometimes used to make use of otherwise wasted HVAC energy to heat pool water, a scheme that’s become more and more popular with commercial applications or extremely large residential swimming pools.

Comments or thoughts on this article? Please e-mail [email protected].